5 Benefits of Using MQTT for IIoT in Tracking and Analyzing Unplanned Manufacturing Downtime

MQTT facilitates efficient data movement for IIoT, ensuring availability of up-to-date manufacturing machine data from various sources. This data can be combined to effectively track and analyze unplanned downtime in your manufacturing or industrial IIoT (IIoT) setup.

In part 1, Tracking and Analyzing Unplanned Downtime in Manufacturing with IIoT, we explored the definition of unplanned downtime, what manufacturers can do to help reduce downtime using IIoT technologies, and the benefits they stand to gain. Now we’ll explore how MQTT and Sparkplug can help manufacturers aggregate data and put it to work to enable machine downtime analytics.

Factory Data Acquisition and Aggregation using MQTT and Sparkplug

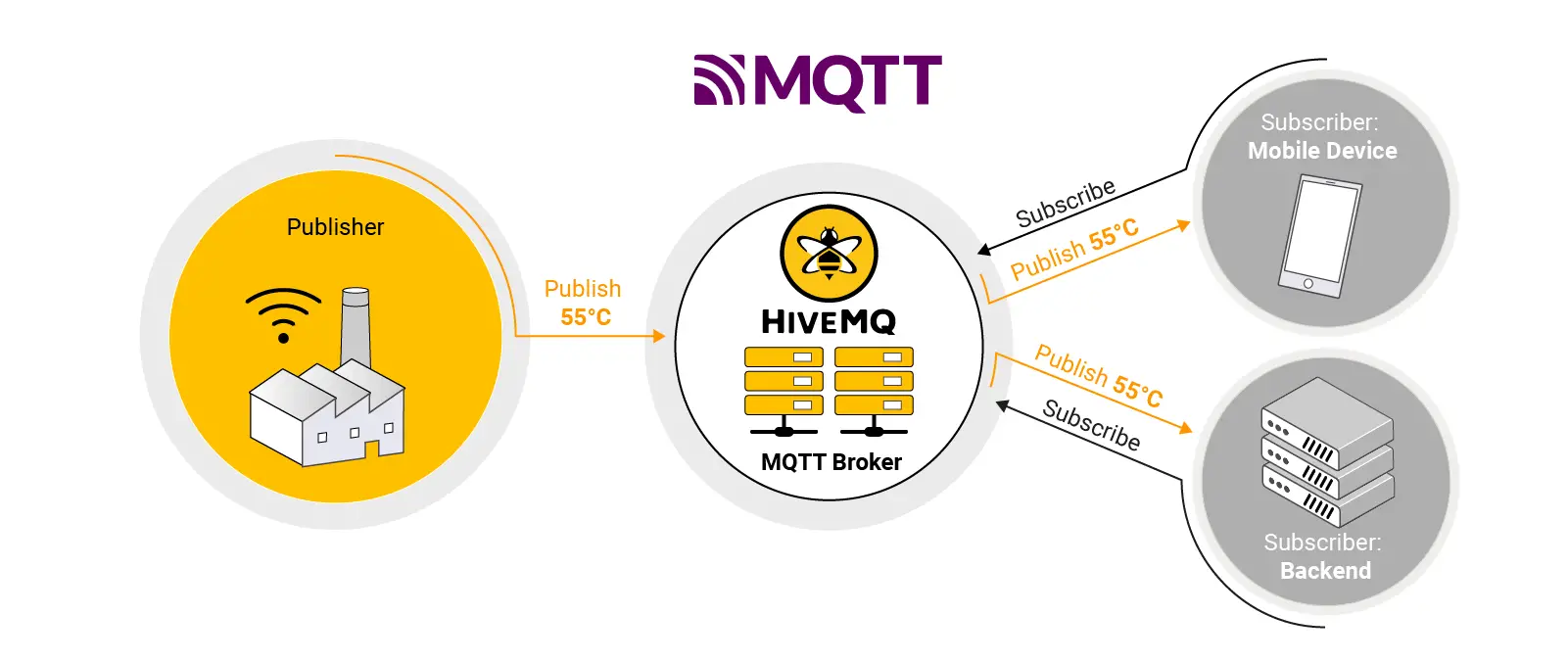

MQTT (see figure 1) is a standard binary publish-subscribe messaging protocol designed for fast and reliable factory machine, systems, and application data transport to enable tracking of unplanned downtime, especially under very constrained conditions. Constraints may include unreliable network connectivity, limited bandwidth,or limited battery power. MQTT is built on top of TCP/IP, which is the go to communication protocol to interconnect network devices on the Internet. For these reasons, MQTT is ideal for IIoT and supports an event-driven architecture.

Figure 1: How an MQTT-based messaging system works

Figure 1: How an MQTT-based messaging system works

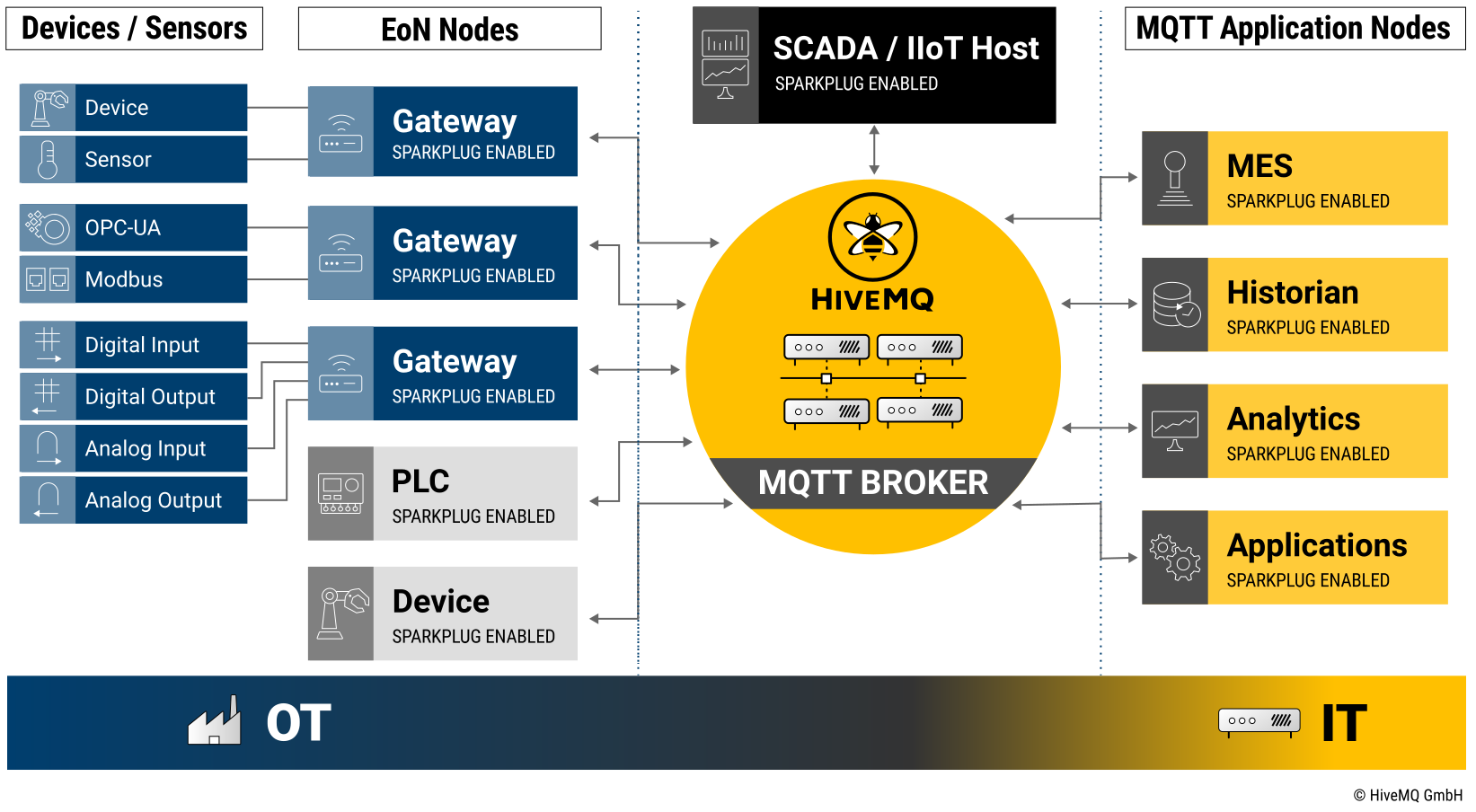

MQTT technology is designed to push data to and from thousands of remote factory machines, systems, and applications across the enterprise. MQTT Sparkplug is a framework that sits on top of MQTT to add more context to manufacturing data. It is an open-source software specification that provides MQTT clients with a framework to integrate various factory data and provide context by defining data models. It provides a consistent way for manufacturing equipment manufacturers and software providers to share contextual factory data, enriching the analysis of the unplanned downtime.

Figure 2 provides an MQTT Sparkplug-based data architecture which shows how the data broker connects multiple machines/processes and applications to enable seamless bi-directional factory data movement between OT and IT systems.

Figure 2: An MQTT Sparkplug-based architecture that supports multiple manufacturing data producers and data consumers to bridge OT to IT and enable downtime analytics

Figure 2: An MQTT Sparkplug-based architecture that supports multiple manufacturing data producers and data consumers to bridge OT to IT and enable downtime analytics

MQTT has gained in popularity when it comes to enterprise IIoT strategy. In a survey conducted by IIoT in 2022, MQTT was the clear winner when it came to data movement tools essential to fulfilling IIoT strategy.

Five Benefits of Using MQTT and Sparkplug in IIoT

1. Unifying a variety of factory machine data types

Software algorithms that help track and reduce machine downtime need a rich variety of data which includes machine data, process data, maintenance records and other information. Each of these data types come in at different rates. MQTT provides a single source of truth that can bring all the data together into one location providing a Unified Namespace (UNS) to then allow these algorithms to easily act upon the data and reduce unplanned downtimes.

2. Achieving Real-time Factory Data Acquisition and Aggregation

For machine downtime tracking and reducing algorithms to be effective especially in edge based solutions, the data and information has to be real time because otherwise the algorithm output will be based on old data which may not lead to the right outcome on machine failure leading to potentially wrong decisions being taken. MQTT enables real time information sharing based on its exception based reporting and the publish subscribe architecture. Also Sparkplug ensures that factory sub-systems changes like new system creation, system teardown or changes are notified in real time to the applications running the algorithms so that the right decisions can be made based on the latest factory system data.

3. Bringing in Contextualized Manufacturing Data

For machine downtime tracking and reducing algorithms to work optimally, apart from having the actual data, having the context around the data is also very important. This is where having a data model that defines the structure of the factory data, where the machine resides with respect to the subsystem, production location etc provides more context to data that can help the predictive maintenance algorithms do a better job with predicting the machine failures. MQTT Sparkplug provides these data models to ensure the data context is better interpreted for richer output. MQTT Sparkplug also supports data tagging and metadata, allowing manufacturers to organize, filter, and search data more effectively. This increased data organization enhances data quality and supports advanced downtime analytics and machine learning applications.

4. Scaling the Flow of Manufacturing Data Reliably

MQTT Sparkplug supports scalable and reliable communication, with mechanisms for handling large volumes of data and ensuring that messages are delivered reliably. It has built in buffering capabilities and Quality of Service (QoS) levels to support high reliability. MQTT Sparkplug can also support a large number of device connections while ensuring that data packets are not lost. This enables advanced downtime measurement algorithms that need high volumes of data to accurately track downtime, its root cause and ensure that it can be minimized.

5. Securely Connecting and Transferring Factory Data

MQTT Sparkplug supports robust security measures, including encryption, access controls, and user authentication, to protect sensitive data and prevent unauthorized access of IIoT data. For most manufacturers, security and privacy risk is the most significant barrier to adopting edge or cloud-based machine downtime analytics technology.

For MQTT communication to happen, a client needs to be authenticated with a broker so that it can send or receive data on a topic namespace. This makes the communication highly secure. The other biggest security feature of MQTT is that all communications are outbound and so there are no open ports to hack into.

Most MQTT brokers provide additional security features. This includes authorization/authentication features like Username & password, OAuth 2.0 (JWT), X.509 client certificates, dynamic permissions, roles-based permissions to name a few. Brokers also typically provide TLS / SSL Encryption for all the communications from and to the broker. Apart from that, HiveMQ offers an Enterprise Security Extension, which enables customers to implement the same security measures that they have on their IT infrastructure like AD, LDAP and others on the broker.

Get Started with Real-Time Tracking and Analyzing to Avoid Unplanned Downtime

The MQTT protocol, along with Sparkplug, is gaining in popularity for factory to enterprise/cloud communications as it is lightweight, reports by exception and provides a lot of features around security, scalability, reliability and others. MQTT is helping to drive IIoT applications that have taken manufacturing verticals closer to eliminating unplanned downtime. IIoT and MQTT-enabled asset management and advanced algorithms have helped in the significant reductions in unplanned downtime, advancing the company’s manufacturing capabilities and efficiencies.

The HiveMQ MQTT platform offers a robust bidirectional and secure MQTT communication set-up with vast integration options with technologies like Kafka, OPC UA, and more, making it one of the most preferred IoT data connectivity solutions for manufacturers. Download HiveMQ today and learn more about our fully-managed and self-managed platforms.

Ravi Subramanyan

Ravi Subramanyan, Director of Industry Solutions, Manufacturing at HiveMQ, has extensive experience delivering high-quality products and services that have generated revenues and cost savings of over $10B for companies such as Motorola, GE, Bosch, and Weir. Ravi has successfully launched products, established branding, and created product advertisements and marketing campaigns for global and regional business teams.