Industrial Intelligence Unleashed: Key Takeaways from Hannover Messe 2025

Hannover Messe is the biggest industrial fair in the world, and this year’s event did not disappoint. The theme was "Energizing a Sustainable Industry," showcasing how Digitization, Industrial Data Management, Smart Manufacturing, Edge, Cloud, and AI technologies help optimize production processes, boost efficiency, and promote sustainable practices. Additionally, there was a strong emphasis on technologies that drive decarbonization and resource efficiency. While the ultimate goal of companies was Carbon Net Zero by 2050, they were pragmatic and focused on what can be done today towards that goal, such as reducing energy consumption, promoting sustainable manufacturing practices, etc.

Representing HiveMQ, I was fortunate to attend the event, where I gained valuable insights that would be useful to share. Some of these are continuations from last year’s themes, which you can find in our 2024 recap.

In this blog post, I’ll dive into a few areas to share what I learned on the show floor:

Industrial Data Management

Industrial AI enabling data-driven decisions in manufacturing

Resurgence of Edge as an alternative/complement to cloud

The IIoT ecosystem

Industrial data security

Laying the Foundation with Industrial Data Management

While AI continued to be the key theme and poster child at the conference, there continued to be a huge emphasis on the foundational platform that will enable all of these use cases to be rapidly developed, deployed, and adopted across the organization. I saw that at many booths from Hyperscalers like AWS and Azure; OEMs like Siemens and Emerson; Data Technology providers like HiveMQ, HighByte, Soffico; and IoT providers like Cummulocity. The other terms that were seen in this area were Industrial DataOps promoted by HighByte and Crosser; Data Fabric promoted by Microsoft; and Distributed Data Intelligence promoted by HiveMQ.

One key takeaway for manufacturers was to maintain focus on a robust scalable/reliable/secure data management platform that is able to achieve multiple functions. These include breaking data silos from various factory systems, enabling data connectivity, ensureing real-time data movement, cleansing data every step of the way as it gets consolidated from its source into plant enterprise levels, and contextualizing data as it traverses through various levels. Last but not least, the data management platform should ensure that a Unified Namespace (UNS)—a single source of truth for all business data—is created at the enterprise level and presents the latest snapshot of business data. This UNS capability ensures that manufacturing data is ready for advanced use cases like AI, Predictive Maintenance, etc.

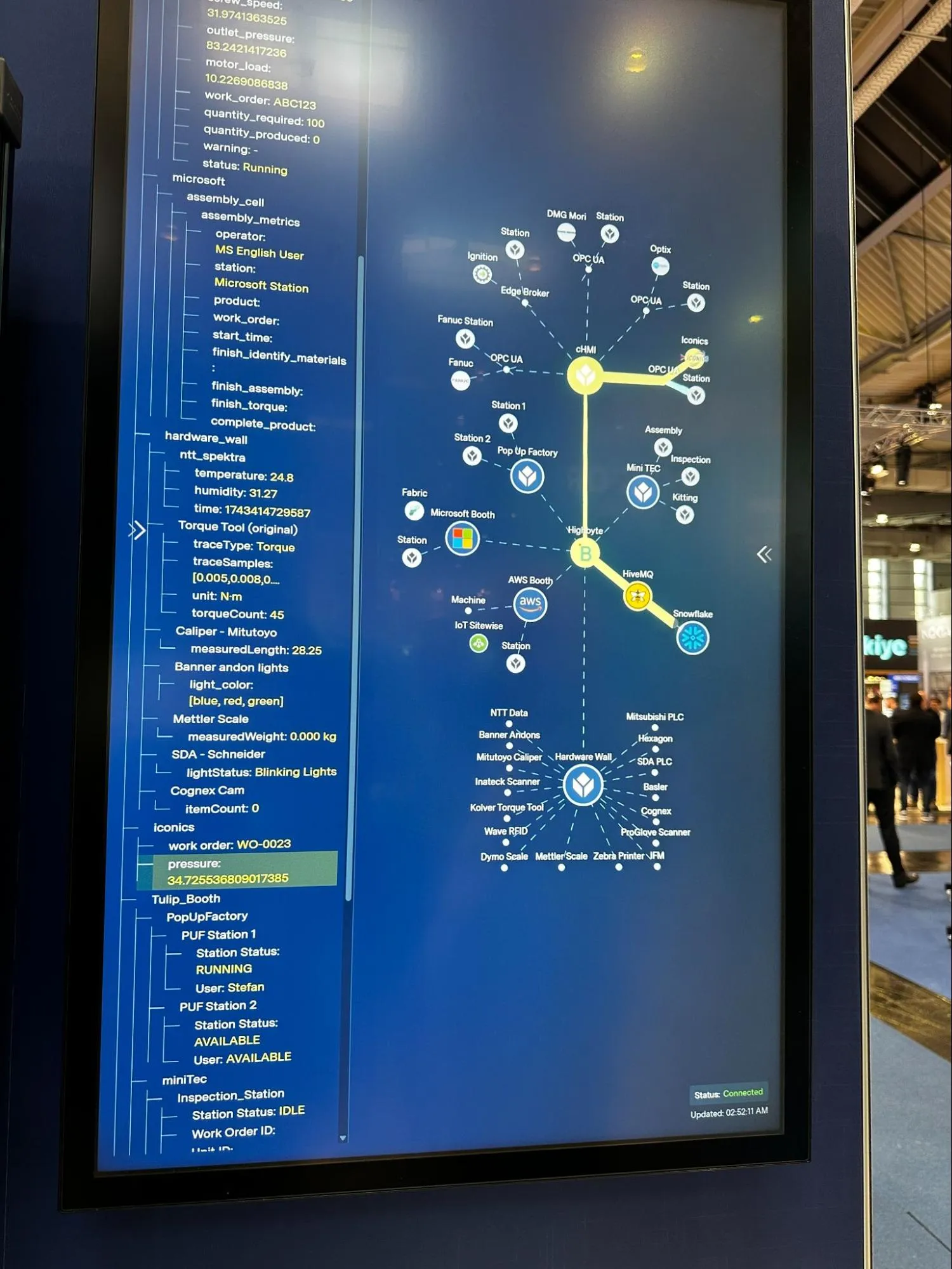

Compared to 2024, UNS certainly seemed to have evolved from a nice concept to a viable solution as providers presented more practical and robust solutions that enabled real customer use cases using UNS. The ProveIt! 2025 conference, which showcased actual UNS use cases, reflected the acceptance of UNS as a viable solution by manufacturing companies. The Hannover Messe 2025 reinforced that interest by various vendors like HiveMQ, HighByte, Litmus, and others demonstrating it. The focus was also on how these vendors came together to enable UNS through robust architectures—this was showcased by Tulip who had a live UNS demo running.

HiveMQ showcased its latest distributed data intelligence product named HiveMQ Pulse, which provides insights at the source, eliminating the need to move data, thereby delivering efficiency and cost savings.

HiveMQ showcased its latest distributed data intelligence product named HiveMQ Pulse, which provides insights at the source, eliminating the need to move data, thereby delivering efficiency and cost savings.

Industrial AI Enabling Data-Driven Decisions

Much like UNS, AI surely emerged from just being a concept to the real deal influencing the manufacturing bottom line at Hannover Messe 2025. The paradigm shifted from possibility to practicality, with clear examples of how AI is already transforming industrial operations on the ground. The various AI exhibitors included foundational model providers like OpenAI, Microsoft, NVIDIA; AI Tooling and Framework Providers like DataRobot and TensorFlow; Vertical-Specific AI Solution Providers like Siemens, Bosch, GE Digital, and SymphonyAI; Robotics and Physical AI Providers like Boston Dynamics, ABB, and Fanuc; and AI Agent and Co-Pilot Developers showcasing use cases like AI optimizing production, boosting efficiency, and enhancing competitiveness.

The Rise of AI Agents, Agentic AI, Generative AI, and Industrial Copilots

Hannover Messe 2025 saw the proliferation of various kinds of AI agents. XMPro showcased its Multi-Agent Generative Systems (MAGS) and Agent Platform Experience (APEX) at Hannover Messe 2025 using the Dell NativeEdge platform and the data supplied by HiveMQ data platform, demonstrating how industrial organizations can deploy collaborative AI agent teams without extensive IT resources or on-site expertise.

Lenovo, in collaboration with NVIDIA, showcased a series of new AI-powered manufacturing tools to help drive agentic AI adoption in heavy industries. Microsoft showcased GenAI use cases to modernize manufacturing and also showcased how its Copilot enables various aspects of a Rolls Royce engine including creating and managing a digital twin of the same. Google showcased the Cortex Framework which provides deployable data product accelerators to enable better analytics and AI experiences with Google's data and AI cloud. ServiceNow showcased how AI Agents, AI agent orchestrator, and AI Agent studio enable customer service workflows. SAP showcased AI-based assembly and warehouse integration.

It was clear—upon seeing these products in action—that they are a very practical and viable option given the advances made in AI technology, the NVIDIA chipsets used for the computer, and the Data Center technologies to support data volume.

Resurgence of Edge as Alternative/Complement to Cloud

The focus on Edge as a viable alternative to the cloud was amply clear at Hannover Messe 2025. Dell Technologies made a huge splash with its NativeEdge industrial platform along with its ecosystem partners to support Edge compute along with Edge-to-Cloud solutions. Siemens showcased their robust Industrial Edge platform which, in partnership with HiveMQ data platform, provided a comprehensive Edge-to-Cloud solution. Advantech, along with its Ecosystem Partners, showcased Edge Computing and Edge AI use cases. Many other vendors—including Edge software providers, hardware vendors, and IoT solution providers—showcased Edge AI, analytics, the ability to run applications on the edge as microservices which can be managed remotely, and using AI in Edge deployment workstreams, and other use cases.

HiveMQ showcased HiveMQ Edge, a small-footprint Edge software that can do protocol translations, add context to data, perform data cleansing, data filtering, as well as store-and-forward data to the enterprise. One of the biggest advantages of the Edge that customers love is that decisions can be quickly made at the data source. The output can then be sent to the enterprise—this minimizes cloud data ingestion costs and streamlines cloud analytics while ensuring data is already in the right format.

Partnerships as a Strategic Business Model to Success

Partnerships play a crucial strategic role in driving success for companies’ bottom line, as highlighted at Hannover Messe 2025. Instead of trying to build everything in-house, many firms are embracing ecosystem collaboration as a core part of their growth strategy. From a complementary capabilities perspective, you could see Microsoft and Siemens collaborating to offer an Industrial Copilot that leverages Microsoft’s AI and Siemens’ manufacturing expertise. From a go-to-market acceleration perspective, we saw Bosch partnering with AWS to bring AI-based predictive maintenance tools to global manufacturing clients. To build modular scalable solutions, you could see Edge Computing Vendors working with AI providers to create interoperable, edge-deployable models.

The partnerships span industrial disciplines and geographies. From a co-innovation and shared R&D perspective, you could see Universities and AI startups collaborating on dexterous robotics or autonomous quality inspection systems. From a globalization and localization perspective, you could see European AI firms partnering with Asian hardware manufacturers to expand into localized factory deployments. From a trust, governance, and standards perspective, you could see Industry consortia like Catena-X promote interoperable, standardized data ecosystems built through partnerships.

It was interesting to see NVIDIA being featured in a lot of partnerships. This makes sense because for any decent AI capabilities, you need a good chipset, and NVIDIA is the right choice for the same. Interestingly, apparent competitors were forging partnerships and showcasing them as they realized that combining forces helped them win together rather than just competing with each other. This also works well for customers as they get to adopt standardized architectures, which enables them to accelerate their Industrial use cases.

Robust Industrial Data Security

Robust Industrial Data Security is becoming a foundational pillar for successful Industrial use cases including AI deployment. It was a hot topic at Hannover Messe 2025. As more factories, machines, and systems become connected and intelligent, securing industrial data across its entire lifecycle is mission-critical for maintaining trust, operational continuity, and compliance.

Zero Trust architecture, which operates on the principle of 'never trust, always verify,' was prominently featured by companies like Palo Alto Networks, Akamai, and Cloudflare, demonstrating how techniques such as role-based access control, authentication, and micro-segmentation enable secure IT and OT integrations. With more AI and analytics moving to the edge (near machines and sensors), securing on-site compute is crucial with techniques like hardware-based trust execution environments, secure boot and firmware integrity checks, and encryption. This was showcased by Fortinet, Barracuda Networks, and ZScaler. AI model security was also showcased—to guard against model inversion, poisoning, or adversarial attacks—by employing techniques like Model Watermarking, Differential Privacy during training, and Robustness Testing against adversarial inputs. These were showcased by companies like Vectra AI, Darktrace, and Cynet.

From Vision to Realization

Hannover Messe 2025 made it clear that Industrial AI is no longer a futuristic promise—it’s a present-day imperative. From intelligent agents augmenting human decision-making to dexterous robots reshaping the labor landscape, the event showcased how AI is transforming the very DNA of industrial operations.

The rise of agentic systems, data-centric architectures, and trusted AI ecosystems highlights a shift toward smarter, more autonomous, and more collaborative industrial environments. However, success in this new era doesn’t come from technology alone—it comes from strategic partnerships, secure data practices, and scalable integration frameworks that align human and machine capabilities.

As companies move from pilots to production, the message from Hannover Messe is clear: those who embrace open ecosystems, invest in trust-driven AI, and scale through collaboration will lead the next industrial revolution. However, to power AI in production, proper data management is necessary for an optimal experience. For more information on HiveMQ data management, contact us and request a free demo.

Ravi Subramanyan

Ravi Subramanyan, Director of Industry Solutions, Manufacturing at HiveMQ, has extensive experience delivering high-quality products and services that have generated revenues and cost savings of over $10B for companies such as Motorola, GE, Bosch, and Weir. Ravi has successfully launched products, established branding, and created product advertisements and marketing campaigns for global and regional business teams.