Leveraging Open Standards like MQTT to Manage Data at the Industrial Edge

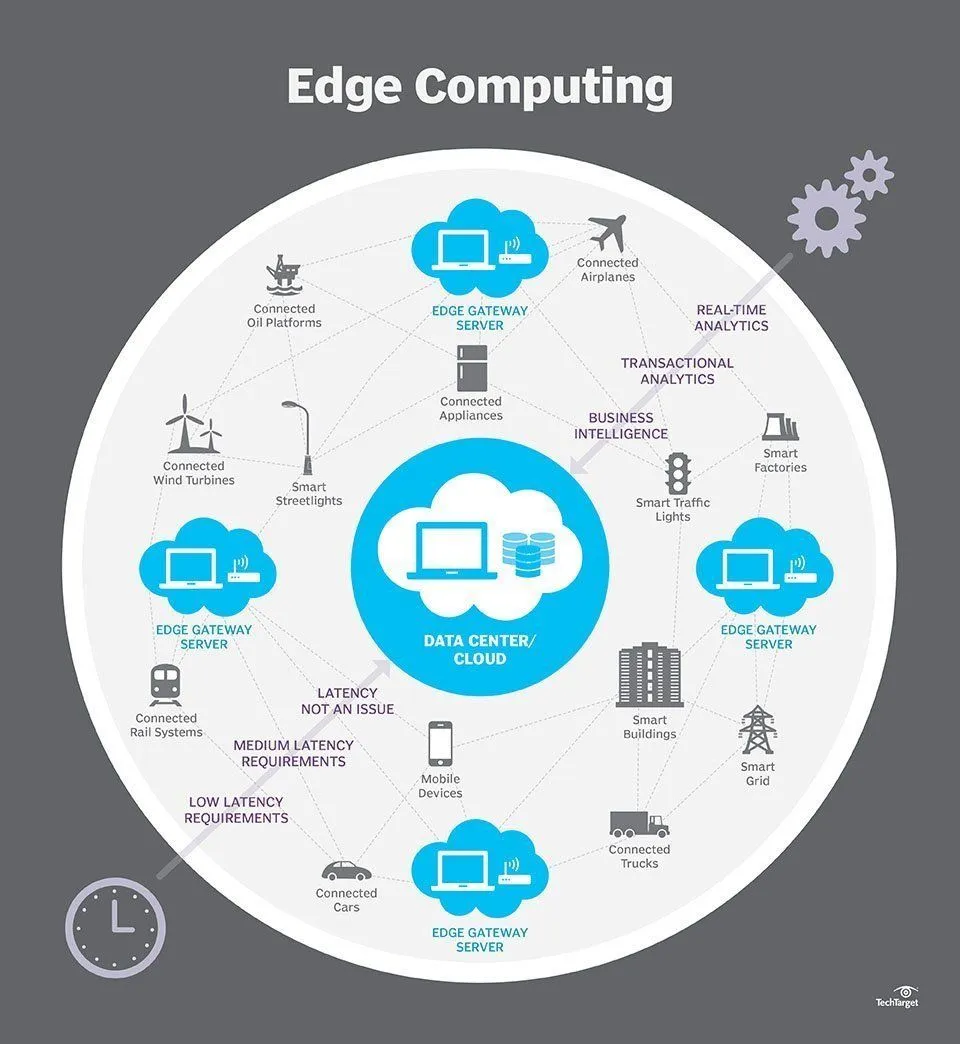

What is Edge Computing

According to IBM, edge computing is a distributed computing framework that brings enterprise applications closer to data sources such as IoT devices or local edge servers. The close proximity to data at its source can deliver strong business benefits including faster insights, improved response times, and better bandwidth availability. Edge computing offers several advantages in industrial applications, particularly in sectors like oil and gas, manufacturing, transportation, and utilities.

According to the 2023 IoT & Edge Commercial Adoption Survey Report conducted by the Eclipse Foundation, 90% of respondents either have already adopted or are considering adopting edge technologies over the next few months.

Source:https://www.techtarget.com/searchdatacenter/definition/edge-computing

Source:https://www.techtarget.com/searchdatacenter/definition/edge-computing

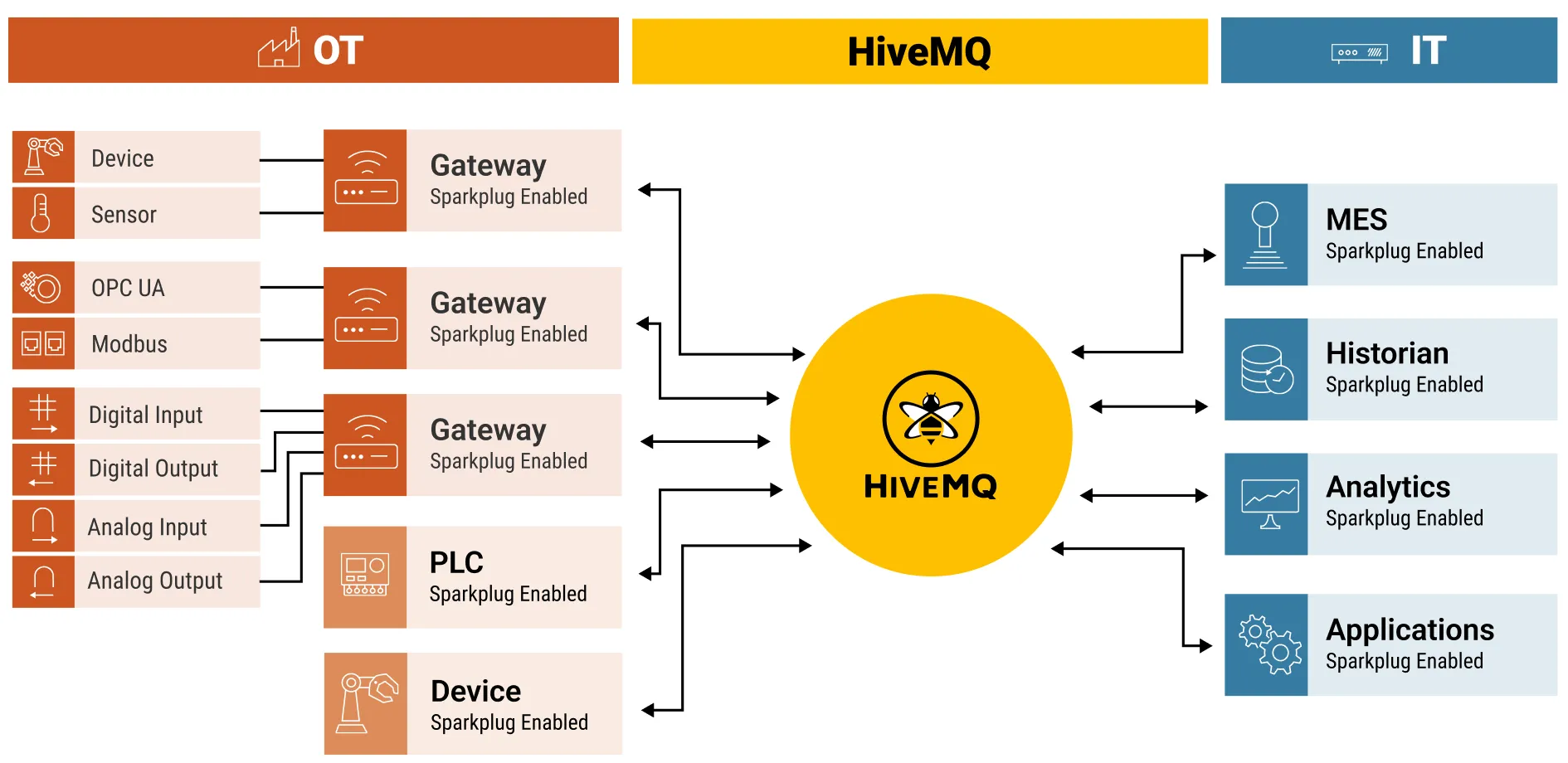

Why use Open Standards like MQTT and Sparkplug at the Edge

MQTT is a lightweight messaging open standard protocol used in IoT for data movement and is designed for efficient communication between devices in low-bandwidth, high-latency, or unreliable networks. As you can see, these are the exact benefits of edge computing. Hence MQTT is very suitable for this purpose. Sparkplug provides additional features like data modeling, topic organization, message types, payload definition and state management especially for smart manufacturing use cases.

Industrial IoT Architecture with MQTT and Sparkplug

Industrial IoT Architecture with MQTT and Sparkplug

According to the Eclipse Foundation report, 75% of organizations are actively incorporating open source into their edge deployment plans.

Use Cases for Edge Computing in real life applications

Typically edge computing techniques are used to collect, filter, process, contextualize and analyze data at or near the network edge for use cases that require:

Low Latency and Real-Time Processing

Local data processing at the edge minimizes the time it takes to analyze and act on data because it eliminates the need to send data to the cloud and back. This low-latency capability is crucial for real-time decision-making.

In predictive maintenance, edge computing enables real-time data analysis from machinery sensors. When a potential fault is detected, alerts can be triggered immediately, preventing costly equipment failure and minimizing downtime. Real-time data processing ensures that decisions are made in milliseconds, which is essential for mission-critical operations like aerospace manufacturing.

Bandwidth Optimization

By processing data locally, edge computing reduces the amount of raw data that needs to be sent to centralized cloud servers. Only important or summarized data is transmitted, which optimizes bandwidth usage and reduces costs.

In smart factories, thousands of sensors monitor machines, processes, and environmental conditions. Edge computing can analyze data locally and only transmit key performance indicators (KPIs) or anomalies to the cloud, reducing the load on the network and minimizing bandwidth costs.

Data Security and Privacy

On-site data processing means that sensitive data does not need to leave the factory floor or industrial site, reducing the risks of interception or tampering during transmission. Edge devices can also enforce localized security protocols.

In aerospace manufacturing, where intellectual property and sensitive data about component manufacturing are critical, edge computing ensures that this data is processed and stored locally, reducing the exposure of sensitive data to cyber threats. Localized data encryption, authentication, and access control further enhance security. In high-risk industrial environments like upstream oil and gas, edge computing enables real-time safety monitoring by processing sensor data from drones, cameras, or environmental sensors locally to detect hazardous conditions or worker fatigue.

Resilience and Operational Continuity

Autonomous operation of edge devices allows industrial systems to continue functioning even if there is a loss of connectivity to the central cloud. Edge computing ensures local decision-making and data processing without relying on the network.

In remote oil and gas monitoring, if the network connection to the cloud is interrupted, edge devices can continue to monitor equipment, detect anomalies, and trigger automated responses such as shutting down equipment to prevent accidents. The system remains operational even in areas with unreliable or limited connectivity.

Scalability for Large-Scale Deployments

Edge computing supports scalable distributed architecture, where each device processes data independently or in collaboration with other edge devices. This enables the deployment of thousands of IIoT devices without overloading a centralized system.

In large-scale food and beverage manufacturing plants, edge devices can be deployed at each machine to monitor performance and quality control. These devices can work independently or in clusters, scaling the system without the need for massive cloud infrastructure expansion. This decentralized approach is essential for the scalability of IIoT systems. For asset tracking use cases in logistics, edge devices track and manage assets across supply chains, providing real-time visibility into asset location, condition, and movement, which is crucial for inventory management and reducing logistics costs.

Interoperability and Flexibility

Edge computing platforms often support multiple communication protocols and data formats, enabling interoperability between different IIoT devices and systems. This flexibility ensures that data from various sensors and machines can be processed and integrated seamlessly.

In automotive manufacturing, where multiple suppliers and systems are integrated on the factory floor, edge computing ensures that data from machines using different protocols (e.g., OPC-UA, MQTT) can be processed locally and shared across platforms, enabling synchronized production and real-time quality control.

Local Machine Learning and AI Capabilities

Edge devices equipped with AI/ML algorithms can run machine learning models locally, allowing for faster and more efficient real-time decision-making without needing to rely on cloud-based processing. This feature is essential for advanced IIoT use cases.

In defect detection systems, cameras and sensors can use AI-powered edge devices to detect product defects in real-time. Machine learning models analyze the visual data locally and flag any anomalies, enabling manufacturers to quickly remove defective products from the line without disrupting production.

Data Filtering and Aggregation

Edge devices can filter and aggregate raw data before it is transmitted to the cloud, ensuring that only relevant and important information is sent. This prevents data overload at the central cloud platform and reduces unnecessary data storage costs.

In energy management systems within smart grids, edge devices at different points in the network can collect and analyze power consumption data locally. They only send relevant aggregated data (e.g., anomalies or usage spikes) to the central platform for further analysis, improving efficiency and decision-making.

Improved Response Times for Autonomous Systems

Instantaneous local decision-making at the edge enhances the responsiveness of autonomous systems. This feature is critical for systems where immediate action is required, such as autonomous vehicles or robotic systems.

In robotic manufacturing cells, edge computing enables real-time control of robotic arms and machinery without delays caused by cloud communication. Robots can autonomously adjust their actions based on sensor feedback, improving precision and reducing the need for human intervention.

Compliance with Industry-Specific Regulations

Edge computing allows companies to maintain compliance with data sovereignty and industry-specific regulations by processing and storing data locally. This is particularly important in industries with strict data handling rules.

In pharmaceutical manufacturing, edge computing can ensure that data related to drug production is processed and stored within specific geographic locations, in compliance with regulations like Good Manufacturing Practices (GMP) or FDA guidelines. Local data governance at the edge helps ensure compliance while reducing legal risks.

Energy Efficiency and Cost Reduction

Local data processing at the edge reduces the need for continuous data transmission to the cloud, which in turn lowers energy consumption and operational costs associated with bandwidth, cloud storage, and processing.

In smart buildings, edge devices monitor energy usage across HVAC systems, lighting, and appliances. By processing this data locally, the system can make immediate adjustments to optimize energy efficiency without constantly communicating with the cloud, reducing both energy consumption and operating costs.

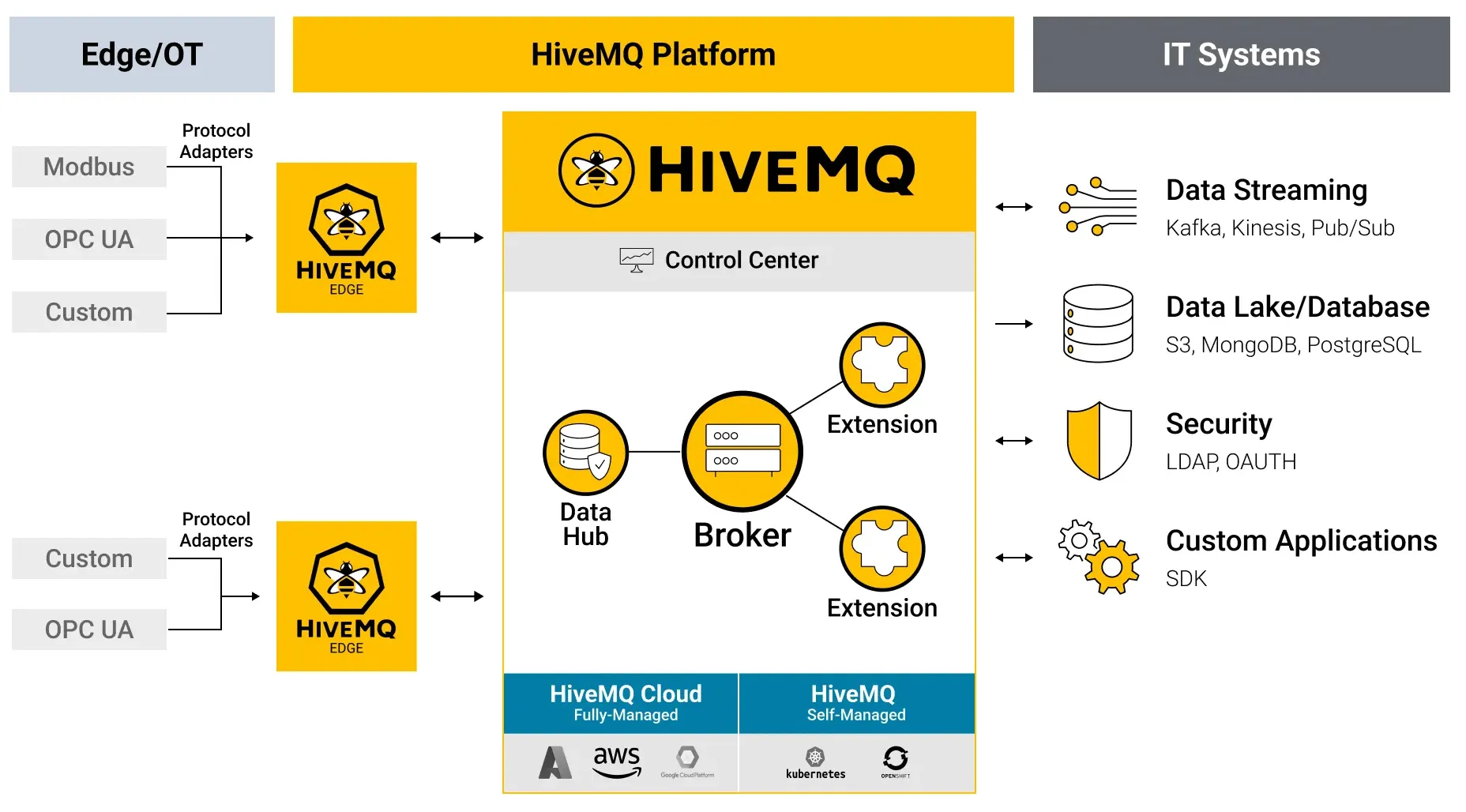

HiveMQ Edge: Enabling Advanced IIoT Use Cases

HiveMQ Edge is a small footprint yet powerful software gateway that compliments the HiveMQ enterprise broker and HiveMQ cloud broker by providing the following functionality:

Protocol Conversion

HiveMQ Edge standardizes industrial edge data from proprietary protocols such as OPC UA, Modbus, Siemens S7, Rockwell Allen-Bradley Ethernet/IP and many more into MQTT to enable a seamless data flow from device to cloud for improved manufacturing operations.

Data Contextualization

HiveMQ Edge offers Data Hub which provides an integrated policy and data transformation engine that validates, enforces, and manipulates data in motion to ensure data integrity, quality and governance across the deployment.

Unified Namespace

Edge supports Unified Namespace (UNS) prefixes which allow contextualization of all industrial data points.

Offline data buffering

Edge supports offline data buffering which brings in the ability to store messages when edge is offline and transmit them when it comes back online.

Edge Broker

HiveMQ Edge serves as an edge data broker, consolidating the data on the industrial sub system and bridging that to the plant, enterprise, or cloud brokers.

HiveMQ Edge architectural diagram

HiveMQ Edge architectural diagram

Edge Computing is a Critical Enabler for IIoT

Edge computing is a critical enabler of IIoT use cases by offering localized data processing, low-latency responses, enhanced security, and improved scalability. It empowers industries to extract meaningful insights from data at the source, enabling real-time decision-making and improving operational efficiency, safety, and reliability. As IIoT systems continue to expand and evolve, edge computing will play an increasingly vital role in enabling more advanced, resilient, and intelligent industrial processes. HiveMQ provides a compelling Edge offering to enable IIoT use cases and to bridge the gap between OT and IT.

Download and try HiveMQ Edge to feel the power of the solution.

Ravi Subramanyan

Ravi Subramanyan, Director of Industry Solutions, Manufacturing at HiveMQ, has extensive experience delivering high-quality products and services that have generated revenues and cost savings of over $10B for companies such as Motorola, GE, Bosch, and Weir. Ravi has successfully launched products, established branding, and created product advertisements and marketing campaigns for global and regional business teams.