Powering the Industrial Edge with MQTT

As more companies embrace Industry 4.0, they are looking to bolster the industrial edge to harness the power of data near the source. The value of edge data increases rapidly when it is used for real-time monitoring and control, which is crucial in industries like manufacturing or oil and gas, where even milliseconds of delay can affect productivity and safety.

According to the 2023 IoT & Edge Commercial Adoption Survey Report, the Eclipse Foundation reports that 90% of survey respondents have already adopted or are considering adopting edge technologies over the next few months. The survey results are not surprising considering that edge computing provides several key advantages in industrial applications, including:

Low Latency: Edge computing reduces the distance data needs to travel by processing it closer to the source. This minimizes latency, ensuring real-time or near-real-time responses. In industrial applications where split-second decisions are crucial, the low latency provided by edge computing is essential for maintaining operations and safety.

Bandwidth Optimization: By processing and filtering data locally at the edge, only relevant information is sent to the cloud or central data center, reducing the amount of data transmitted over the network. This optimizes bandwidth usage, lowers data transmission costs, and alleviates network congestion.

Improved Reliability: Edge computing enables applications to continue functioning even when connectivity to the central cloud is disrupted. This ensures the uninterrupted operation of critical systems in industrial environments where network outages or latency issues can have severe consequences.

Modernizing the Edge

Legacy technologies like OPC-UA and Modbus were optimized for machine-to-machine communication, but present significant interoperability challenges today, preventing seamless communication between diverse industrial edge devices and systems. These heterogeneous systems hinder modernization and digital transformation, and the only way to achieve true interoperability is to adopt a modern standards-based communication protocol like MQTT (Message Queuing Telemetry Transport).

MQTT is a lightweight, open-standard protocol tailored perfectly for the industrial edge. MQTT offers unparalleled flexibility and efficiency, enabling streamlined data exchange across disparate devices and platforms with minimal overhead. Its publish-subscribe architecture ensures robust, real-time communication while its support for lightweight clients makes it ideal for resource-constrained environments typical of the industrial edge. By embracing MQTT, industries can transcend the confines of proprietary protocols, unlocking a new era of interoperability, scalability, and agility at the industrial edge.

Impediment to Change

Impediment to Change

As businesses strive to embrace Industry 4.0 and leverage the immense value of their data, they encounter a formidable challenge: the existing machinery and devices, often entrenched in proprietary protocols, pose a significant barrier to cost-effective replacement. Herein lies the critical need for an MQTT gateway (or industrial edge protocol converter), a sophisticated software solution designed to translate proprietary protocols into MQTT seamlessly.

By deploying this transformative technology, enterprises can swiftly bridge the gap between legacy systems and the MQTT standard, facilitating a rapid transition to Industry 4.0 without costly hardware upgrades. This approach not only preserves existing investments but also represents the most expeditious pathway to unlocking the full potential of Industry 4.0.

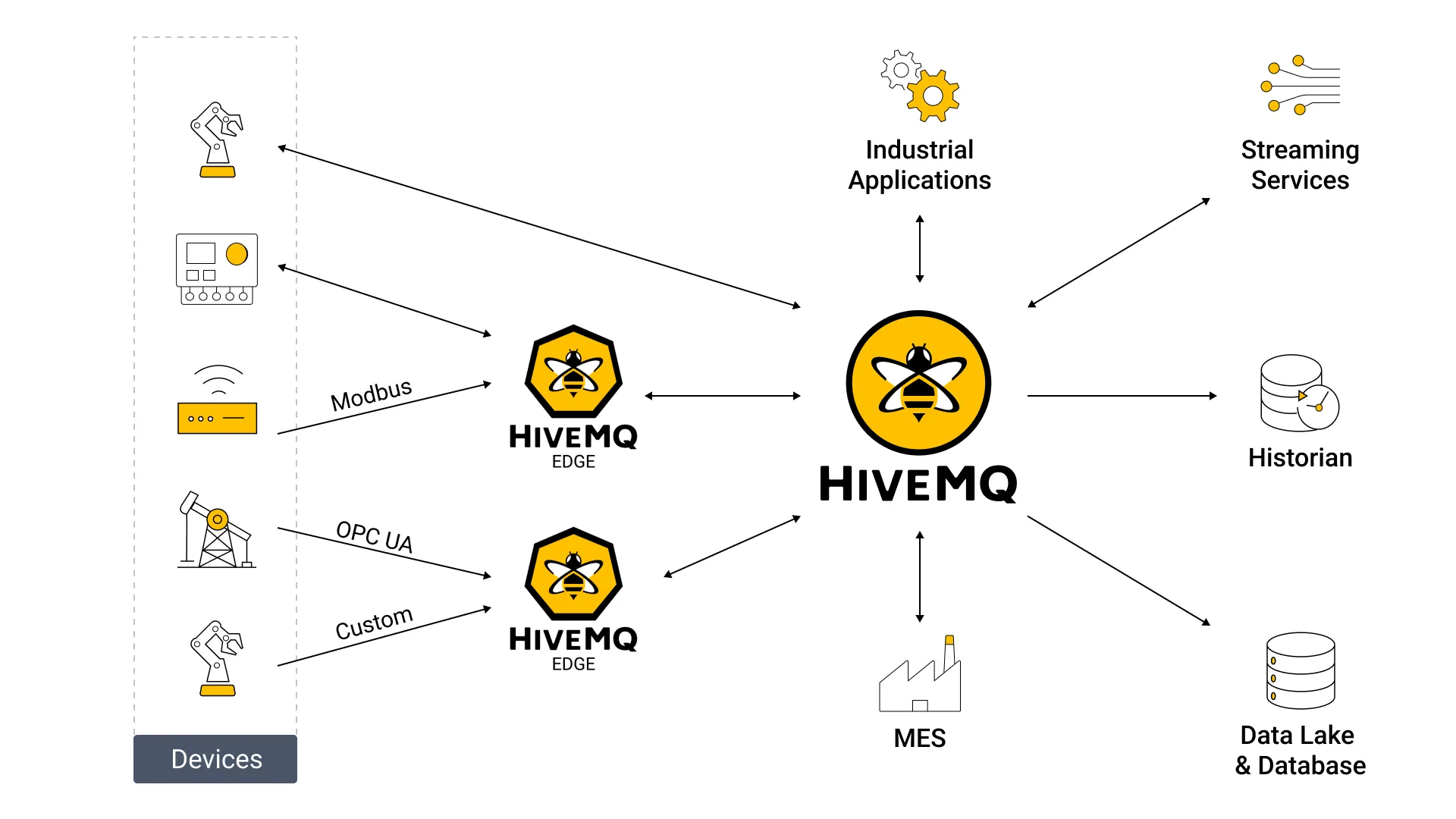

A Modern IIoT Architecture Built with HiveMQ Edge, the Edge MQTT Gateway

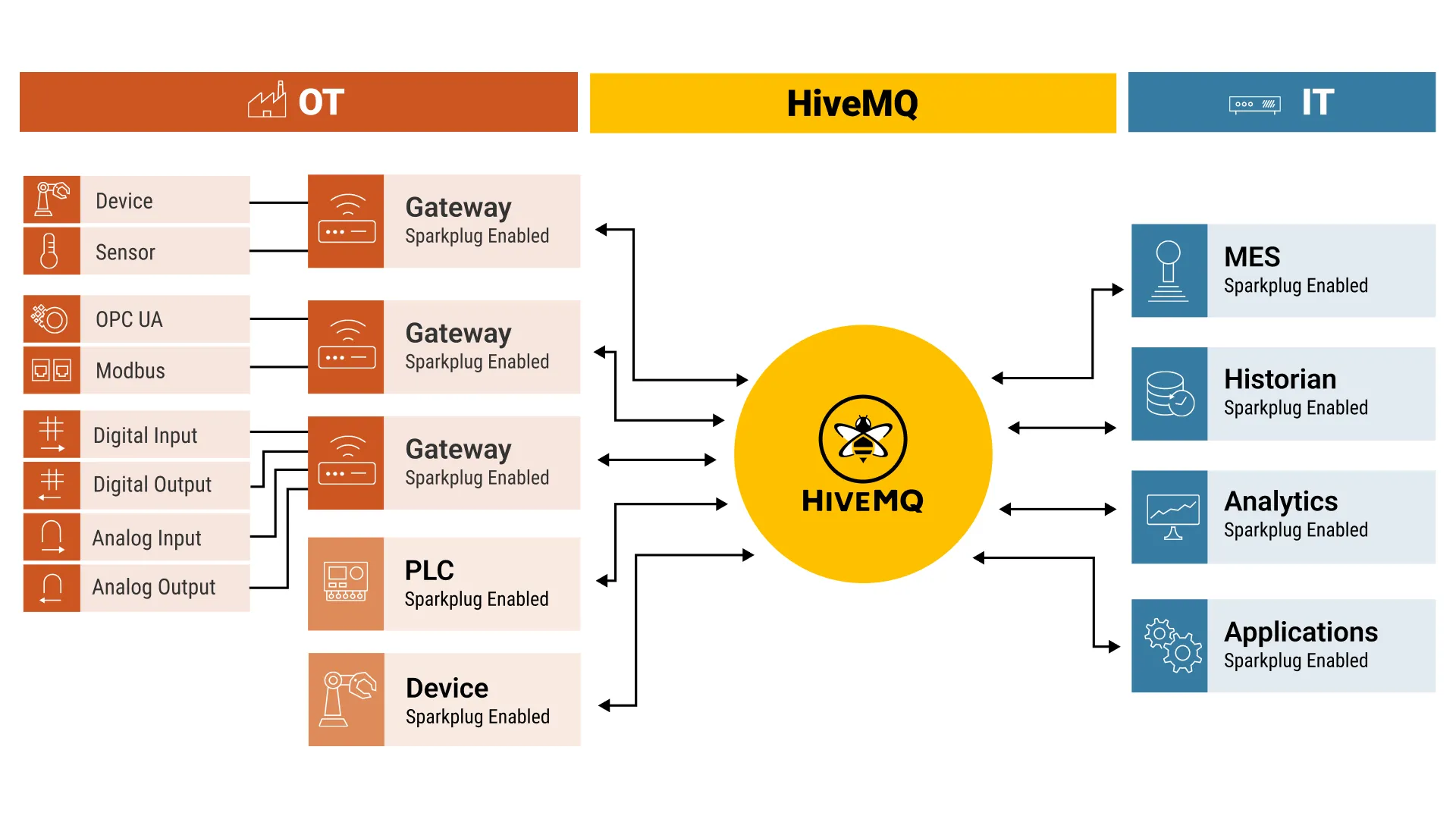

A modern industrial architecture must solve these challenges with a centralized data hub in the middle, seamlessly sending data from the edge to cloud and bridging the Operational Technology (OT) to Information Technology (IT) gap.

The key requirements for this type of Edge gateway includes:

The key requirements for this type of Edge gateway includes:

Protocol conversion: It must convert diverse OT protocols into a unified format, such as MQTT. It should also support easy adoption of custom protocol adapters that can drop in to support any protocol.

Standardization: It must adopt and continue to evolve to support the latest standards in MQTT, like MQTT 3.1.1, MQTT-SN, and MQTT 5.

Data Normalization: It must support frameworks like Sparkplug and Unified Namespace, which add additional context and naming hierarchy to industrial data.

To address these needs, HiveMQ Edge was released last year as an open-source, software-based edge MQTT gateway that has gained thousands of downloads and many successful deployments.

What’s New in HiveMQ Edge?

Today we are happy to announce the latest version of HiveMQ Edge which provides the following new benefits to help users derive even more value from data at the edge.

Improving Data Quality at the Edge with Data Hub

Having good data quality is critical for advanced IIoT use cases such as cloud-based Artificial Intelligence (AI) and Machine Learning (ML) data modeling and analytics. With the high cost of data ingress and egress on the cloud, it is essential that only validated data makes its way to the cloud. For example, advanced data use cases might need a timestamp in HH:MM:SS format to make its analysis effective. Making sure that all the data is validated at the edge and goes to the cloud in the right format is the most efficient and cost-effective for the customer.

Data Hub on the Edge, an integrated policy and data transformation engine, addresses this issue. It enables improvement in IIoT data quality and integrity by helping to define and enforce the required data quality standards. This ensures that the accurate and validated data is fed into AI and ML applications to build high-quality predictive maintenance models.

HiveMQ Edge has the policy designer built into its user interface. The UI provides a modular canvas where customers can drag, interconnect, and configure policy components to build a full-fledged data policy.

Improving Reliability at the Edge with Offline Buffering

Industrial networks are not always robust, meaning connectivity and bandwidth are typically limited for IIoT use cases. When data is being moved from edge to cloud, if connectivity is lost for some time, there is no easy way to buffer the data and resend it when connectivity is reestablished. The result is that data is lost, and enterprise or cloud applications find it difficult to interpret it effectively. Missing mission-critical information could negatively affect decision-making processes and operational insights derived from the data.

The offline buffering, or store and forward functionality, allows HiveMQ Edge to queue and save messages on disk in case of a connection failure and publish those messages after the connection is restored, ensuring zero data loss.

Try HiveMQ Edge

Unifying OT data and sending it to IT systems is a challenge and a high priority for Industry 4.0 initiatives, and HiveMQ Edge is helping companies to bridge the OT-IT gap to achieve seamless edge-to-cloud data flow. The new Data Hub and offline buffering features are available as part of our commercial offerings. The core of HiveMQ Edge remains open source and will continue to evolve to support additional protocols, standards, and data frameworks.

Try it now by downloading HiveMQ Edge to experience the power of the solution. Contact us for a trial license to test out the new commercial features.

Ravi Subramanyan

Ravi Subramanyan, Director of Industry Solutions, Manufacturing at HiveMQ, has extensive experience delivering high-quality products and services that have generated revenues and cost savings of over $10B for companies such as Motorola, GE, Bosch, and Weir. Ravi has successfully launched products, established branding, and created product advertisements and marketing campaigns for global and regional business teams.