What are the Benefits of Digital Transformation for the Automotive Industry?

Automotive manufacturers face several pressures such as supply chain disruptions, unplanned downtime, quality control issues, and increased regulation of plant operations that are impacting their ability to improve operations and meet increasing demands. Automotive manufacturers are increasingly turning to the integration of digital technologies like Industry 4.0 and Industrial IoT (IIoT) to solve data management problems.

Increase Overall Equipment Efficiency (OEE)

Measure the performance, availability, and quality of equipment and find areas for improvement.

Reduced Downtime

Predicting failures allows for scheduled maintenance, minimizing unexpected breakdowns.

Improve Operational Efficiency

Monitor KPIs, identify areas of inefficiency, streamline processes, and take action to improve productivity.

Reduce Supply Chain Disruptions

Enhance supply chain visibility for better inventory management and faster response to disruptions.

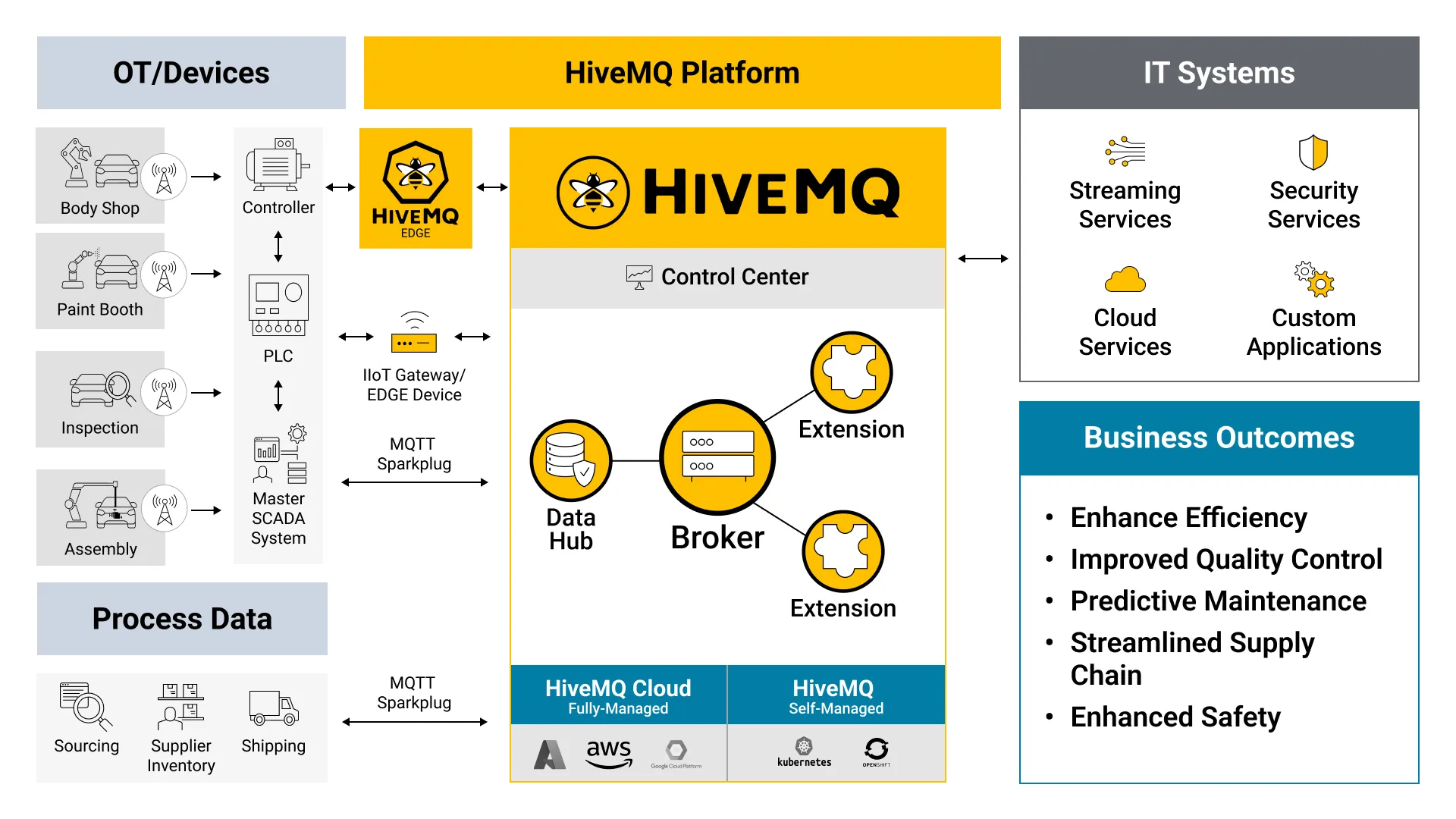

Why HiveMQ for Automotive Manufacturing?

HiveMQ solves the challenges of data collection and movement in manufacturing by adding a reliable, scalable and secure data abstraction layer between OT and IT systems that enables heterogeneous machines and processes to work together seamlessly even in constrained environments. The key benefits are:

Business Critical Reliability

Operate mission-critical systems reliably 24/7 with zero message loss and redundant clustering technology.

Scalability to Support Growth

Add any number of sites and scale to millions of connected devices seamlessly with a linear design for scalability

Flexible Integration

Focus on your core business instead of using developer resources with OT-IT data integration into enterprise applications and infrastructure like Apache Kafka.

End-to-End Security

Ensure applications and data meet the highest security standards with end-to-end encryption and configurable security controls.

Observable Insights

Troubleshoot and keep all factory systems running as planned with tools and metrics for transparency and observability

Simple-to-Deploy

Achieve rapid time-to-value with a platform that is flexible enough to deploy on-premise, in any cloud, or via the fully-managed and feature-rich HiveMQ Cloud offering.

HiveMQ has delivered the stability and reliability that we require for our system. We have been using HiveMQ for 4 years and the broker has not gone down. It is rock solid, completely reliable. This is very important since we can’t stop the factory assembly line.

Marius Hertfelder

/Mercedes Benz

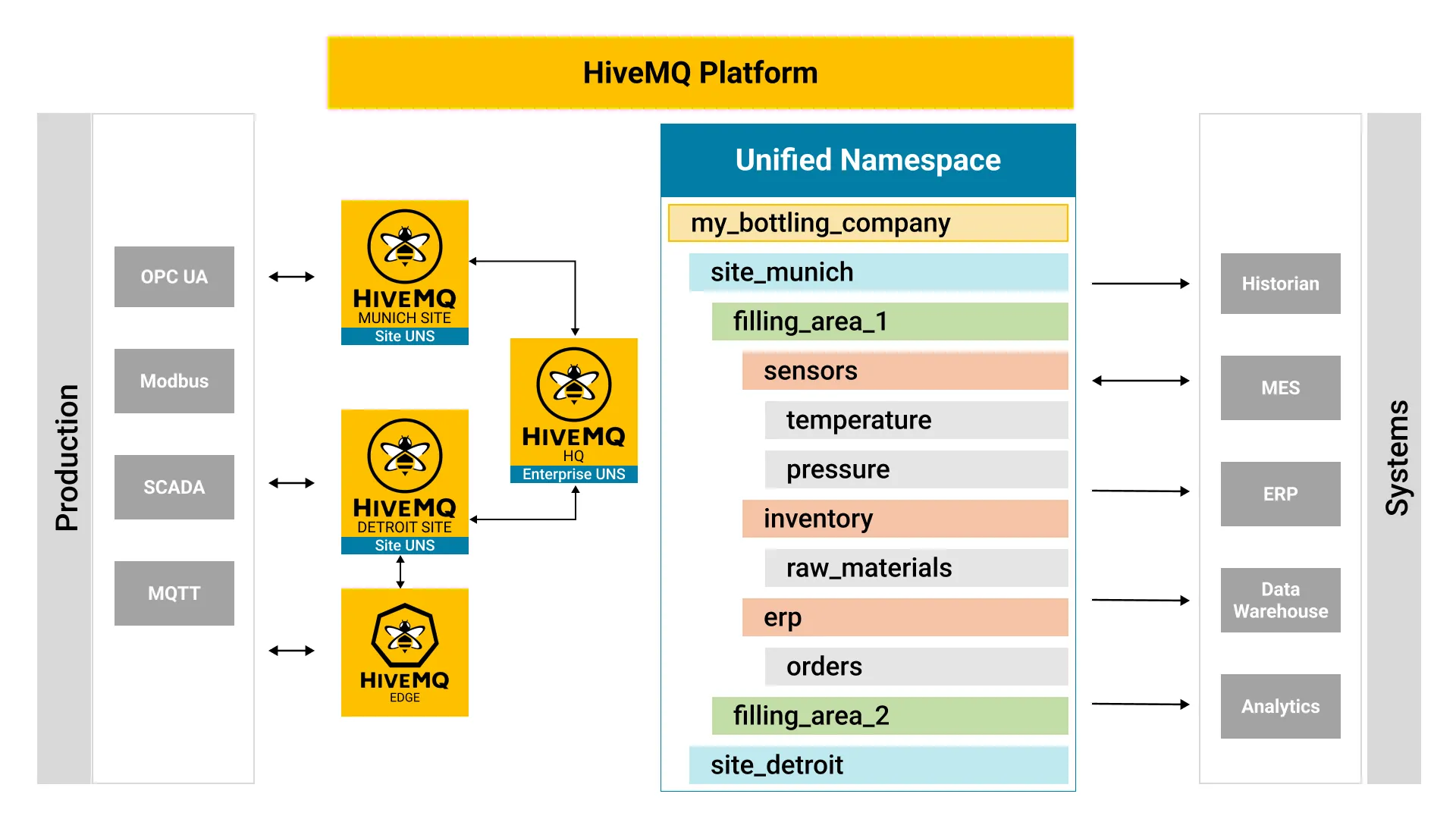

Unified Namespace (UNS)

HiveMQ can help you build a Unified Namespace (UNS), an innovative approach that gathers data from various industrial IoT (IIoT) systems, adds context, and transforms it into a format that other systems can easily understand.

Key Trends in Automotive Manufacturing

For automotive manufacturers, staying ahead of the curve is the key to maintaining competitiveness and maximizing productivity. Manufacturers are leveraging advanced technologies to drive innovation and streamline production.

Unified Namespace

Unified Namespace (UNS) is a concept for managing industrial data with a hub and spoke model that serves as a single source of truth for a business's current state and events.

AI and Machine Learning

AI and ML are used to optimize manufacturing processes, enhance quality control, and predict equipment failures for informed decision-making and autonomous operations.

Data-Driven Factory (IIoT)

Using technology to create highly connected, data-driven environments allows manufacturers to optimize production processes, enhance efficiency, and reduce downtime.

Advanced Robotics

Collaborative robots (cobots) and automated guided vehicles (AGVs) are used to improve precision, enhance efficiency, and streamline production processes.

HiveMQ MQTT Platform for Optimizing Automotive Manufacturing

To optimize operations in the automotive industry, the primary focus of digital transformation lies in data collection and movement. Manufacturing machines, processes, and applications generate valuable data captured and stored using key ingestion technologies. This data is transferred from operational technology (OT) to information technology (IT) systems and stored in data centers or enterprise clouds. This data-rich environment facilitates advanced initiatives like machine learning, AI, adaptive control, and digital twins, ultimately driving operational efficiency and improvement.

Business Value Pricing

HiveMQ prices its offerings based on the value you derive, not on speed and feeds. There is no need to count messages or integrations, rather we align to specific business goals and outcomes. Specifically, we offer pricing based on:

Request Quote

Number of Plants or Locations

How many plants or locations do you need to support and over what time period?

Complexity of Each Location

How many devices and protocol types need to be supported per plant?

Deployment Options

Do you need us to run the software for you, or will you self-manage the deployment? What is the relationship between plants and headquarters?

Time Commitment

Are you looking for a multi-year deal or to renew each year?

Key Resources for Automotive Manufacturing

Knowledge-packed resources showcasing how MQTT, MQTT Sparkplug, and HiveMQ platform can transform Automotive Manufacturing.

Learn about the trends in optimizing global operations and supply chain for automotive manufacturing in this whitepaper. Gain insights into how MQTT addresses connectivity challenges, how Sparkplug adds additional data context, and how IIoT technologies are helping automotive manufacturers digitize their operations.

Discover the power of HiveMQ's MQTT solutions for the automotive manufacturing industry in our datasheet. This guide provides insights into the application of MQTT technology in automotive manufacturing, and how it can revolutionize data management for optimized and efficient operations.

Watch this webinar to discover how to quickly and effectively implement, measure, and improve Overall Equipment Efficiency (OEE) to get performance improvements of 10% to 30%. Understand and improve OEE to identify areas of improvement, reduce downtime, increase throughput, and ultimately enhance overall productivity.

Read more about how MQTT Sparkplug solves IIoT interoperability challenges by adding context to MQTT, decoupling data consumers and producers, ensuring immediate discoverability, and establishing a single source of truth.

Get started with HiveMQ today

Choose between a fully-managed cloud or self-managed platform. Our experts can help you with your solution and demonstrate HiveMQ in action.