Modernizing the Smart Manufacturing Industry with MQTT

Smart manufacturing is driving the manufacturing industry to modernize its software infrastructure to create smart factories. Whether you call it Industry 4.0 or the Industrial Internet of Things (IIoT), manufacturing is in the midst of a significant transformation. A key motivation in this push to modernize is that real-time data and dynamic decision making yield meaningful performance improvements for businesses.

Current manufacturing infrastructure is costly to maintain, creates barriers to the distribution of data, integrates poorly with other systems, and blocks corporations from capitalizing on the advantages that digitalization creates. Successful transition to the next generation of manufacturing will require the adoption of new technologies that can integrate outdated existing systems with modern new systems.

In this whitepaper, we investigate the business drivers for modernization, technical challenges of adopting new technology, important emerging architecture patterns for modernizing software infrastructure, and recommendations for linking the different levels of automation in a factory with new MQTT-based messaging infrastructure. The goal of this whitepaper is to provide guidance to senior technology leaders in the manufacturing industry on how the MQTT protocol can serve as the key technology for developing the modern connected smart factory.

Business Drivers to Create Smart Factories

Businesses today face the question of how to make machines smarter, processes leaner, factories more efficient, and productivity higher. The proliferation of sensors in manufacturing environments provides a phenomenal amount of valuable data. Advances in cloud computing make it possible to integrate machine learning, artificial intelligence and advanced analytics to quickly respond to the changing dynamics on the factory floor. Increasing consumer demand for high-quality, personalized goods is fueling the need for more flexible manufacturing processes that respond to customer and market demands. For many manufacturers, developing the ability to cost-effectively realize extreme customization, a so-called batch size of one, is essential.

Movement is toward a more flexible form of manufacturing that improves factory efficiency and optimizes intra-facility logistics. Measuring and increasing overall equipment effectiveness (OEE) is a central element of the process:

Increase the availability of equipment by avoiding unplanned downtime

Ability to analyze everything and continuously increase the quality of production

Fine-tune the performance of machines and processes

The end result of the drive toward modernization is the digitization of manufacturing to create smart factories.

Current State of Manufacturing

The current state of manufacturing is an important consideration in modernization projects.

Brownfield vs Greenfield: Most modernization projects are for existing factories (brownfield) rather than the creation of a brand new factory (greenfield). Brownfield projects must accommodate the continuous operation of the factory, the security of existing systems, and the integration of existing systems from various vendors.

Data Silos: Existing factories typically have equipment from a wide variety of vendors that produce data in proprietary formats. These formats often create data silos that hinder deep level analysis across the entire factory operation.

IT/OT Priorities: A successful modernization project needs to include experts from the operations side (OT) and the enterprise IT side (IT). These two groups often have different perspectives and priorities when it comes to introducing new technologies. The primary concerns of OT staff are usually the continuous operation of the factory and the security of the equipment. If new technology can cause a piece of equipment to fail, this might create a health and safety issue for employees or factory downtime that results in lost business for the organization. IT staff are typically more accepting of risk. The IT organization may be interested in the use of new cloud technologies and agile development methodologies to respond as quickly as possible to customer requirements. System failures can often easily be addressed by redeployment of the software to a cloud service.

Goals for Smart Manufacturing

Most companies that set out to modernize their plants and manufacturing processes have one or more objectives in common:

Bring the agile software delivery and development mindset of IT into the OT world of the factory. This involves introducing traditional IT technologies and processes into OT.

Achieve a faster mean time to recover by reducing downtime of equipment with predictive maintenance and automating software updates. If an outage or standstill occurs, it is vital to have a fast recovery time. Every second and minute of lost production generates waste and unnecessary expense.

Enable centralized command and control to visualize the overall manufacturing process in one plant or across multiple factories.

Implement a consistent and flexible software architecture that eliminates barriers and connects processes into a unified whole.

Levels of Integration to Achieve Smart Manufacturing

The key to modernization is breaking down the silos of data that exist at different levels of automation. In OT, an automation pyramid is frequently used to visualize system requirements. To completely integrate a factory, consistent and reliable bidirectional movement of data within and between levels must be present.

Level 0: The base of the pyramid is the field level. This is the level of sensors, signals, machine, and real-time capabilities. At this level, microseconds and milliseconds are extremely important.

Level 0: The base of the pyramid is the field level. This is the level of sensors, signals, machine, and real-time capabilities. At this level, microseconds and milliseconds are extremely important.

Level 1: On the PLC (programmable logic controllers) or control level, sensing and manipulating takes place within seconds. Real-time is also important here for production processes predictability.

Level 2: This level handles process management for monitoring and supervising. Here, SCADA (supervisory control and data acquisition) systems and HMI (human-machine interface) give operators a first visualization of what’s going on within the factory.

Level 3: The next level is for MES (manufacturing execution systems). This is where manufacturing operations management takes place. Here, we move off the factory floor into the top floor and measure activity in hours.

Level 4: Finally, at the top, there are ERP (enterprise resource planning) systems for business planning and logistics. Processes on this level are typically calculated in days and months.

To achieve integration, the data flow must work between systems on the same level as well as between the levels.

Architecture Patterns for Smart Factories

In general, manufacturing software modernization projects can be divided into two basic categories: connection within a single factory and connection between multiple factories.

Intra-factory Connection

Intra-factory connectivity is focused on connecting the different areas of a factory and ensuring information can flow through the different levels of automation.

It is sometimes useful to view the factory as 4 distinct areas:

It is sometimes useful to view the factory as 4 distinct areas:

Automation area: Factory machines, sensors and gateways. Data needs to be able to flow between the machines and the sensors and gateways. The gateways are typically used to communicate with other areas in the factory architecture.

Manufacturing area: Systems used to control the factory equipment such as SCADA and MES systems.

Factory area: Systems used to manage the entire factory such as PLM and OEE systems.

Cloud: Connectivity to the enterprise IT systems of the organization that allows for deeper integration between the OT and IT systems.

Inter-factory Connection

The push toward inter-factory connectivity is increasing. Projects in this space can involve companies with facilities that are grouped in a single area or spread around the globe. The geographic location or number of factories is not the primary concern. These projects want to bring data from each factory to the cloud to gain total visibility. Inter-factory integrations allow companies to profit from all the data that is generated across all factories and gain deep insights into how the business is operating.

The push toward inter-factory connectivity is increasing. Projects in this space can involve companies with facilities that are grouped in a single area or spread around the globe. The geographic location or number of factories is not the primary concern. These projects want to bring data from each factory to the cloud to gain total visibility. Inter-factory integrations allow companies to profit from all the data that is generated across all factories and gain deep insights into how the business is operating.

Factory IIoT Message Bus

A related concept that is rapidly gaining traction is IIoT bus. The idea is that everything, from the bottom up to the cloud, needs to get connected. An IIoT message bus solution connects not only the things that are important from a business messaging perspective, but also many sensors and actuators. This solution recognizes the fact that factories generate a lot of data that is currently not considered critical enough to capture. In this model, additional sensors are added to a factory to provide additional data that adds context for deeper analysis. For example, vibration sensors that can provide the data needed for predictive maintenance when machine vibrations change. MQTT is the usual choice for these sensors and actuators.

A related concept that is rapidly gaining traction is IIoT bus. The idea is that everything, from the bottom up to the cloud, needs to get connected. An IIoT message bus solution connects not only the things that are important from a business messaging perspective, but also many sensors and actuators. This solution recognizes the fact that factories generate a lot of data that is currently not considered critical enough to capture. In this model, additional sensors are added to a factory to provide additional data that adds context for deeper analysis. For example, vibration sensors that can provide the data needed for predictive maintenance when machine vibrations change. MQTT is the usual choice for these sensors and actuators.

Implementation of a New Messaging Infrastructure

Implementation of these architecture patterns require a new messaging infrastructure for moving data within the levels of factory automation and between factories. For brownfield projects, the current method of data exchange is often through proprietary protocols that have made it difficult to share information between systems and have resulted in data silos that make it difficult to introduce any type of data analysis. Some organizations have used the OPC-UA standard to implement a messaging infrastructure but with mixed results. Because OPC-UA solutions tend to be complicated and expensive to implement, widespread adoption within the vendor community and industry has been limited.

When considering a new messaging platform and protocol there are some key technical challenges and requirements that need to be addressed by any new system, including:

It must be possible for reliable bi-directional connectivity between the different systems and areas of a factory. The same protocol must be able to send and receive a message from a factory equipment, MES system, PLM system and a traditional IT system.

A new messaging infrastructure must make it possible to promote interoperability between the different systems of a factory. The messaging infrastructure needs to be based on a standard protocol that can easily be implemented by a wide range of vendors.

Security immediately becomes a huge issue when factories and equipment are connected directly or indirectly to the Internet. Failure to implement adequate security from the start can expose factories to enormous risks.

Introduction to MQTT

MQTT is a popular messaging and data exchange protocol for IoT projects. The MQTT protocol was originally created to allow a SCADA system to control and monitor oil pipelines. Key points:

Simple, lightweight publish/subscribe protocol

Efficient bi-directional connectivity between clients and broker

Designed for reliable communication over unreliable Internet and WiFi networks

Includes different quality of service (QoS) levels

Uses lightweight clients make it easy to implement

Integrates easily into existing IT security infrastructure

Connecting the Smart Factory with MQTT

The MQTT messaging protocol is well suited to be the standard for new messaging systems within a factory. MQTT is an ISO 20922 standard that has become the de-facto standard for connecting IoT devices and is increasingly popular within smart manufacturing and Industry 4.0.

The publish/subscribe architecture of MQTT is what makes it so interesting as a messaging protocol for manufacturing modernization projects. This architecture decouples communication between the different clients which allows different vendors and different systems to implement MQTT independently.

All MQTT clients push data to a central MQTT server/broker that forwards the message to the subscribing clients. MQTT clients can include factory equipment, specialized sensors and actuators, SCADA systems, MES, etc. Each of these clients can send and receive data in a format that is independent of a vendor-proprietary protocol. Having different vendors implement MQTT support for their systems creates interoperability between the many different systems deployed in a factory.

MQTT supports bi-directional messaging between various clients. The publish/subscribe protocol allows for telemetry data to be sent from factory equipment to the cloud. At the same time, an enterprise manufacturing system can generate a command to be sent down to the factory floor. The central MQTT broker tracks all the client connections and the subscribed topics for each of the clients.

Integration with existing security systems is easily achieved with MQTT. MQTT messages can be sent using TLS to ensure that data is sent through a secure channel. MQTT brokers are able to integrate with existing authorization and authentication systems to achieve device authentication and roles-based authorization for directing MQTT messages.

Intra-factory Interactions with MQTT

MQTT can be used to implement intra-factory communication between the different areas and systems. Integration of the automation and manufacturing areas (levels 0-3) requires reliable data exchange between various machines, PLCs, and sensors that have very little memory or computing power. MQTT’s lightweight nature and low bandwidth requirements are specifically designed to handle communication over this type of equipment. Standard PLCs such as Siemens S7 or Opto22 usually ship with the ability to consume and push MQTT data straight out of the box. The majority of SCADA and MES systems on the market come with support for MQTT.

MQTT can be used to implement intra-factory communication between the different areas and systems. Integration of the automation and manufacturing areas (levels 0-3) requires reliable data exchange between various machines, PLCs, and sensors that have very little memory or computing power. MQTT’s lightweight nature and low bandwidth requirements are specifically designed to handle communication over this type of equipment. Standard PLCs such as Siemens S7 or Opto22 usually ship with the ability to consume and push MQTT data straight out of the box. The majority of SCADA and MES systems on the market come with support for MQTT.

What is important here is that MQTT provides bi-directional messaging that is suitable for everything from the factory floor on up in the cloud. MQTT is used in the manufacturing area for exchanging data between the MES system and the SCADA system. The same device that publishes data can consume data and all systems can potentially use the same messaging protocol to communicate. Beyond level 3, MQTT allows for seamless integration from the factory to the cloud. MQTT brokers deployed in the cloud can integrate factory information into enterprise systems and enterprise data lakes. MQTT messages can also be sent back into the factory from an enterprise IT system.

Inter-factory Interactions with MQTT

MQTT is specifically designed for the type of secure and reliable data transfer over the Internet that connecting multiple smart factories requires. MQTT brokers on the factory floor can use bridging to push MQTT data to a large MQTT broker cluster in the cloud. Performant MQTT brokers in high-availability clusters can scale to thousands of messages per second from hundreds of sites.

An MQTT broker cluster deployed into an enterprise IT data center can forward all data from each individual factory into enterprise services, such as Apache Kafka for streaming, MongoDB to create a data lake, machine learning services, or data analytic services. A centralized MQTT broker can send commands and updated data to remote factories and even specific equipment within a factory. This reflects the true bi-directional capabilities of MQTT.

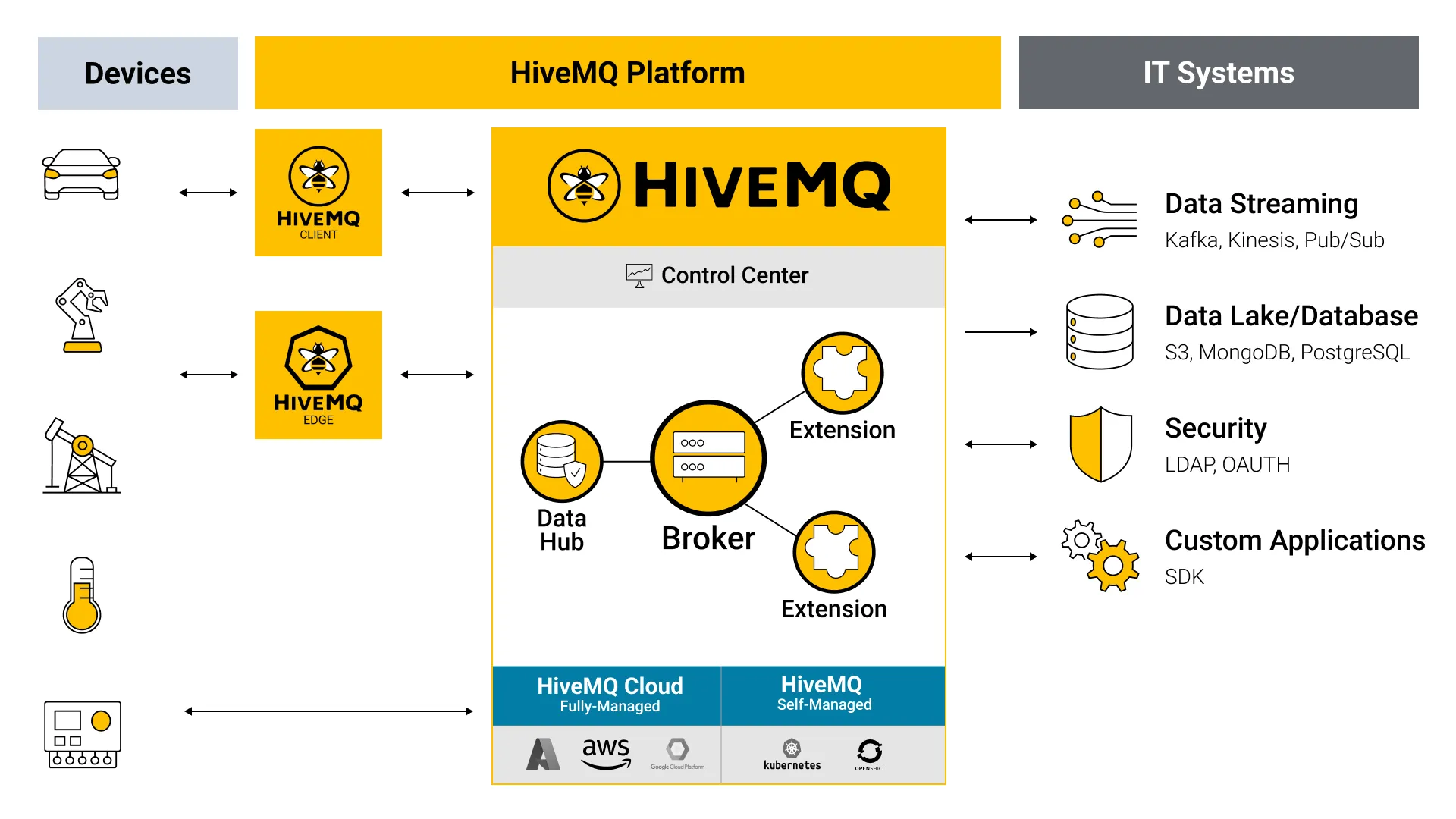

HiveMQ: An Enterprise MQTT Platform for Smart Manufacturing

HiveMQ is uniquely positioned to provide a solid solution for modernizing manufacturing infrastructure with MQTT. HiveMQ is an MQTT messaging platform that delivers fast, efficient, and reliable movement of data to and from connected IoT devices. The HiveMQ messaging platform is used by over 130 customers, including Audi, BMW, Daimler and Liberty Global, to run production IoT applications using MQTT.

Open-source MQTT brokers such as Mosquitto are occasionally used in manufacturing use cases. However, since Mosquitto can not be deployed into a cluster environment or provide professional technical support to manufacturing customers, it is a risk to deploy it into a production environment.

HiveMQ addresses the key technical challenges of modernization:

Bi-directional Messaging: HiveMQ supports MQTT’s bi-directional messaging to allow data transfer from factory equipment to the cloud and from the cloud back to specific factory equipment. HiveMQ also supports MQTT’s three quality of service (QoS) levels to control whether a message is sent at most once, at least once, or exactly once. This makes it possible to establish reliability rules for specific messages.

Security: HiveMQ ensures secure transfer of IoT data with industry standards such as TLS, secure WebSockets, and state-of-the-art cipher suites. Support for authentication and authorization includes X.509 certs, username/password, IP-based authentication, and an API that allows for custom authentication, authorization, and permission logic such as OAuth 2.0 integration.

The HiveMQ Enterprise Security Extension (ESE) makes it easy to integrate third-party enterprise security systems into HiveMQ, including support for authentication and authorization using SQL databases, OAuth 2.0 and LDAP. ESE also supports:

Preprocessing of authentication and authorization data from MQTT clients and x509 client certificates

Structured access log for tracking security-related device information

Fine-grained authorization rules to specify permissions for specific clients or a group of clients

Access control for the HiveMQ Control Center

Scalability: HiveMQ scales with the underlying hardware. The non-blocking multithreaded approach allows more than 10,000,000 concurrent device connections while maintaining extremely fast throughput and adding minimal latency. Automatic elastic and linear scalability at runtime is critical to support the message throughput rate that inter-factory communication frequently requires.

High-Availability Clustering: HiveMQ is architected with a truly distributed and masterless cluster architecture, which means there is no single point of failure and the cluster can grow and shrink at runtime without losing data or availability. Support for Kubernetes, OpenShift, and DC/OS makes it possible to automatically scale HiveMQ to meet the requirements of most IoT applications.

Extension Framework: HiveMQ has an open API and flexible extension framework that makes it possible to integrate HiveMQ and IoT data into existing enterprise systems. The extension framework allows developers to quickly create extensions for custom data processing, device authentication, and device authorization mechanisms. HiveMQ also provides a marketplace of pre-built extensions for Kafka, MongoDB and other systems.

The HiveMQ Enterprise Extension for Kafka is of particular interest for manufacturing use cases. Apache Kafka is a popular open-source streaming platform that is widely used to share data between back-end systems and applications. The HiveMQ extension solves the difficulty of using Kafka for IoT by seamlessly integrating MQTT messages into the Kafka messaging flow.

Full support of all MQTT 5: HiveMQ provides full support for MQTT 5, the most recent version of the MQTT protocol. MQTT 5 includes new features that make it easier to develop reliable systems and integrate the MQTT data into other systems and is the preferred choice for manufacturing.

HiveMQ is 100% compliant with all versions of the MQTT specification. MQTT 3 and MQTT 5 clients can communicate with HiveMQ simultaneously and all features such as topic wildcards, persistent sessions with offline queuing, retained messages, and quality of service levels are available at scale.

Conclusion

Many manufacturing organizations are beginning the process of modernizing their factory operations to achieve greater efficiency and flexibility. This modernization process requires a substantial upgrade of the existing software infrastructure. A cornerstone of factory modernization is the ability to break down the data silos that prevent a business from obtaining an accurate picture of their overall operation.

Several factors favor use of MQTT as the standard protocol for modernizing the messaging infrastructure of a factory. The MQTT protocol uses a publish/subscribe architecture that efficiently moves data between factory equipment, factory OT systems (MES and SCADA), and enterprise IT cloud services. MQTT also provides the bi-directional messaging that a scalable, reliable, and secure messaging system requires. Due to its performant scaling capabilities, 100% implementation of all MQTT 5 features, and professional support services the HiveMQ Enterprise MQTT broker is well suited as the MQTT platform used to operate the messaging system that is needed for modern digitized manufacturing.