Gaining Visibility Into Discrete Manufacturing Processes With MQTT

Discrete manufacturing refers to the production of distinct, individual items or units that can be easily identified and counted. This type of manufacturing involves the assembly of components or parts into finished goods, where each item can be distinguished from the others. Typical discrete manufacturing industries include Automotive, Electronics, Aerospace, Machinery and Medical Devices.These industries often use bills of materials (BOMs) and quality control measures in the process. Discrete manufacturing allows for customization, flexibility, and efficient production of a wide range of products.

Common Processes of Discrete Manufacturing

Production Planning and Scheduling

Discrete manufacturing requires careful planning and scheduling for the entire production process to ensure that the necessary parts and components are available when needed. The scheduling defines how much time each production stage takes and how much each person should work to ensure that the production is completed on time. Production schedules need to be optimized to minimize waste and maximize efficiency. Hence supply chain data visibility is very important.

Optimization of Batch Sizes and Lead Times

The batch size highlights the volume of production, and the lead times refer to the time taken for the entire process. Both these parameters impact the efficiency of production and hence must be optimized for better output. Having real-time visibility and accuracy of the data is very important.

Common Systems of Discrete Manufacturing

To enable efficient operation within discrete manufacturing, various systems are used. Here are some:

Computer-Aided Design (CAD)

CAD software is used for designing products, conceptualizing ideas to consider finer details that ensure the end product is flawless. This tool performs rapid design calculations and simulations, helping create accurate and precise product designs.

Computer-Aided Manufacturing (CAM)

Computer-aided manufacturing enables automation of the management process, allowing tracking of the production process, resources, and transportation.

Enterprise Resource Planning (ERP)

ERP implementation gives better control and visibility over the inventory and the entire production process. With the help of ERP, the platforms check different types of data and information and make it accessible and available at all points.

Product Lifecycle Management (PLM)

PLM ensures management of the entire lifecycle of the products from the time of conceptualization until they are finally ready to be dispatched.

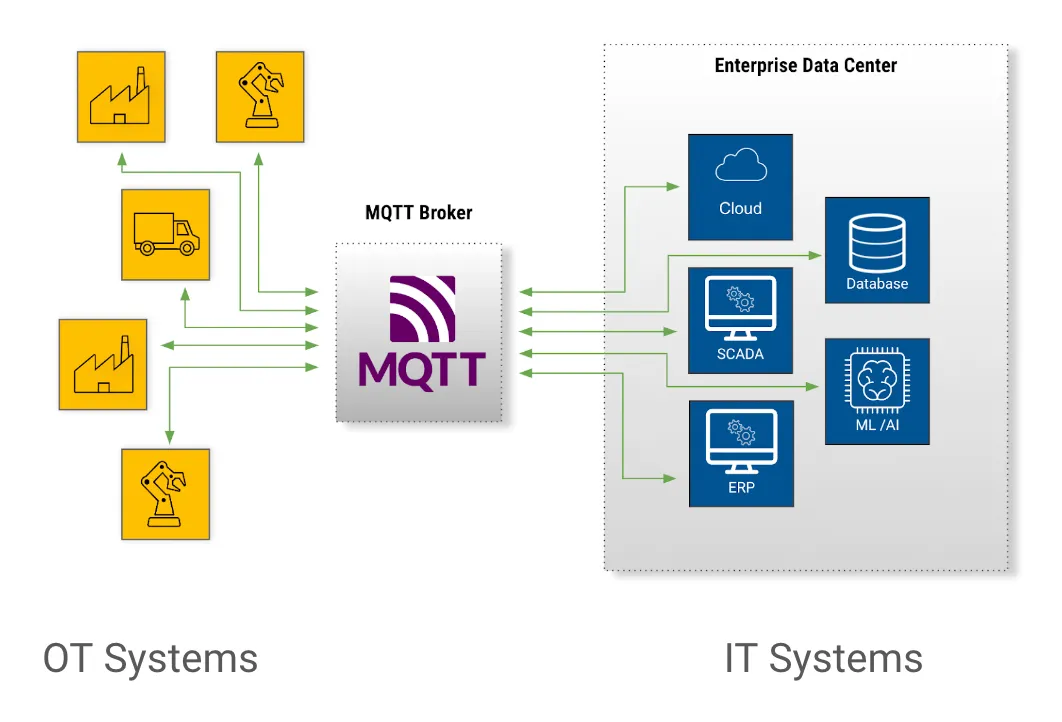

Industrial IoT (IIoT) and MQTT as an Enabler to Connect Systems

IIoT plays a significant role in discrete manufacturing to help connect various OT systems through sensors and Programmable Logic Controllers (PLC) with the IT systems mentioned above. This OT-IT connection enables data exchange and digital transformation use cases where, for example, the order data in the ERP system needs to be combined with the production data in the PLM so that forecasting, planning, and scheduling can happen properly. IIoT enables these systems to talk to each other and create a single pane of glass through a messaging technology like MQTT.

MQTT is a lightweight, publish-subscribe messaging protocol designed for low-bandwidth, high-latency, or unreliable networks which are typically seen in discrete manufacturing. MQTT plays a significant role in enabling various use cases in discrete manufacturing. Here are some of the ways MQTT facilitates discrete manufacturing applications:

Real-time Data Communication

MQTT enables real-time communication between devices, systems, and applications in discrete manufacturing and facilitates connecting them to the enterprise and/or cloud to support advanced data use cases like Predictive Maintenance, Remote Monitoring, Digital Twins and Advanced Analytics. MQTT also facilitates seamless machine-to-machine communication, allowing manufacturing devices to exchange data and coordinate actions without significant latency. This is crucial for monitoring and controlling in discrete manufacturing, ensuring that data is exchanged quickly and efficiently.

Scalability

MQTT is highly scalable, allowing it to support a large number of devices, systems, and applications simultaneously. In discrete manufacturing, where numerous devices, systems, and applications are deployed across the production floor, MQTT's scalability is essential for handling diverse data sources. HiveMQ, which provides an enterprise-grade MQTT broker, has additional scalability features and has benchmarked 200M concurrent connections.

Efficient Bandwidth Usage

MQTT is designed to be efficient in terms of bandwidth usage. In a manufacturing environment, where network bandwidth may be limited, MQTT's lightweight protocol ensures that data can be transmitted efficiently without putting additional strain on the network infrastructure.

Reliability and Quality of Service (QoS)

MQTT supports different levels of Quality of Service, allowing manufacturers to choose the appropriate level of reliability for their specific use case. This is crucial for applications where reliable data exchange is essential, such as in remote monitoring of critical equipment. MQTT offers additional reliability by supporting retained messages, where the last message sent on a particular topic is retained by the broker. This feature is particularly useful in discrete manufacturing for ensuring that devices connecting to the network receive the latest relevant information upon connection. HiveMQ MQTT broker provides additional reliability features including masterles cluster architectures ensuring no single point of failure, reliable communication, and zero downtime upgrades.

Security

MQTT inherently offers security to the communication as it is based on subscription to topic namespaces. So any client that is not subscribed to a topic will not receive the message. Apart from that, additional security features can be implemented on MQTT including user id/password, TLS encryption, X.509 client certificate authorization and other mechanisms to secure discrete manufacturing communications. HiveMQ MQTT broker offers additional security features including Security Extension, secure communications, and others.

Publish-Subscribe Model

MQTT follows a publish-subscribe model, where clients can publish messages to specific topics, and other clients can subscribe to those topics to receive the messages. This model is well-suited for discrete manufacturing scenarios where different components need to be informed of relevant events or changes in real-time. In addition to that, data frameworks like Sparkplug and concepts like Unified Namespace provide additional ways to contextualize and organize the data in an efficient manner.

Edge Computing Integration

MQTT is often used in conjunction with edge computing in discrete manufacturing. Edge devices, applications, and systems use MQTT to communicate with each other locally, communicating selectively with the server/cloud thereby reducing the need for all data to be sent to a centralized server. This can improve response times and reduce latency. Edge gateways like HiveMQ Edge enable translating data from various protocols like OPC UA, Modbus, and Siemens S7 into MQTT and bring the data into the broker for processing.

MQTT is a Game Changer for IIoT Data Communications in Discrete Manufacturing

IIoT in discrete manufacturing brings about improvements in efficiency, quality, maintenance, and overall operational effectiveness. By enabling data communications using a reliable and efficient communication mechanism like MQTT, discrete manufacturing systems can efficiently support real-time monitoring of various devices, processes, and applications on the factory floor and support advanced data use cases. The connectivity resulting from MQTT empowers discrete manufacturing to digitally transform its operations, which leads to more efficiency, reduced costs, better customer experience, and more profitability. Contact us to learn more about how we can help you with your discrete manufacturing use cases.

Ravi Subramanyan

Ravi Subramanyan, Director of Industry Solutions, Manufacturing at HiveMQ, has extensive experience delivering high-quality products and services that have generated revenues and cost savings of over $10B for companies such as Motorola, GE, Bosch, and Weir. Ravi has successfully launched products, established branding, and created product advertisements and marketing campaigns for global and regional business teams.