How Data Management Fuels Success in the Industrial AI Era

The ARC Advisory Group conducted their 29th annual ARC Industry Leadership Forum in February 2025 in Orlando, FL. The forum is aimed at process manufacturing industries like Pharmaceuticals, Food & Beverage, Chemical, Oil & Gas and Renewables. The overall theme for this year’s conference was “Winning in the Industrial AI Era” with a lot of focus on how to increase business performance through AI, Digitalization, and Sustainability. The various forum topics and the vendor booth talking points explored the latest advancements and trends in industrial platforms, industrial AI, industrial data fabrics, and industrial cybersecurity and how these technologies can drive sustainability and digital transformation.

Here are some of the key insights.

Industrial AI, Metaverses, and Data Fabric

Industrial AI, a subset of the broader field of artificial intelligence (AI), refers to the application of AI technologies (including Generative AI) in industrial settings to augment the workforce in pursuit of growth, profitability, more sustainable products and production processes, enhanced customer service, and business outcomes. At the conference, there was a lot of buzz around Industrial AI, including Agentic AI. Some new breakthroughs around AI such as Large Language Models (LLMs) for AI for industrial use cases were showcased. Some useful conceptual frameworks for governing and prioritizing Industrial AI use cases were discussed as well. General consensus was that while these are important for the future of Industrial companies, the AI use cases need to be aligned to the company culture and processes. Otherwise, these AI projects would not be successful or would not get widespread adoption within the organization.

The Industrial Metaverse is a virtual world that simulates real-world systems, such as factories, machines, and cities. It uses technologies like digital twins, augmented reality (AR), virtual reality (VR), and artificial intelligence (AI) to create a realistic, interactive experience.

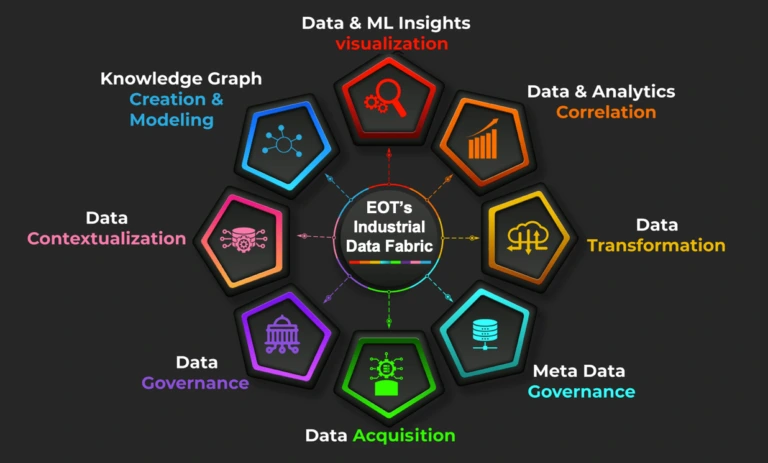

Data fabric refers to a data management and integration architecture that connects and manages data across an organization. It allows businesses to access, govern, and share data more efficiently.

There were some insights provided for how AI relates to the Industrial Metaverse, Industrial Data Fabric (Fig. 1). AI acts as the core intelligence engine within the Industrial Metaverse, leveraging vast amounts of data from an Industrial Data Fabric to analyze patterns, make predictions, and optimize industrial processes in real-time, enabling smarter decision-making and significantly enhancing operational efficiency across the manufacturing landscape.

Figure 1: Interaction of Industrial AI, Metaverse, and Data Fabric. Image source

Figure 1: Interaction of Industrial AI, Metaverse, and Data Fabric. Image source

Data Management solution providers like Inductive Automation, HiveMQ, and HighByte showcased Unified Namespace and how it plays a part in managing data at the Industrial Edge, contextualizing data, consolidating data across the enterprise, and preparing data for AI use cases including Industrial Metaverse, Gen AI, and Agentic AI, etc. Watch this interview discussing smart manufacturing at the 2025 ARC Forum.

One of the sessions in the data fabric category that I got to participate in was the session by Colin Masson (ARC Advisory Group’s Director of Research) titled “Industrial-grade Data Fabric: Getting from Enterprise-grade to Industrial-grade.” This was a voice of customer session with a few end users presenting how data fabric enabled their data journey. This was followed by a panel discussion. HiveMQ’s customer representative David Maglaya from Moderna presented on how increasing operational efficiency and reducing machine downtime using MQTT and UNS enabled Moderna to deliver mRNA medicines.

A major focus was also set on open source solutions in industrial software, hardware, and the intersection of the two. Organizations like Universal Automation, COPA, OPC Foundation, VDMA, Codesys, and Software Defined Automation discussed how an open architecture based on open standards benefits all of the vendors and the end customers to achieve more affordable, efficient solutions.

A major focus was also set on open source solutions in industrial software, hardware, and the intersection of the two. Organizations like Universal Automation, COPA, OPC Foundation, VDMA, Codesys, and Software Defined Automation discussed how an open architecture based on open standards benefits all of the vendors and the end customers to achieve more affordable, efficient solutions.

Energy Transition and Industrial Sustainability

Energy transition and sustainability are now being woven into the core business strategies of industrial companies, who now have the mandate and opportunity to tackle environmental and social challenges. Formal Environmental, Social, and Governance (ESG) strategies are being formulated while companies are trying to get innovative with technologies. The conference extensively covered how companies are tackling decarbonization, new tracking requirements, and the many complex threads associated with the energy transition and improved environmental stewardship. It was clear that these efforts are being balanced with the demands for financial performance, reliability, and ongoing digital transformation.

Some of the specific topics and discussions tackled decarbonization strategies and best practices, Hydrogen technologies, innovations in emissions reporting, digital product passports and regulatory compliance, and modernizing operations for enhanced efficiency and sustainability. This was particularly important for some of the O&G OEMs present, such as Exxon Mobile, BP, Marathon Petroleum, and some of the process manufacturing companies like Lilly, Dow, Air Liquide, and others.

Asset Performance Management

Asset Performance Management incorporates Industrial IoT (IIoT) and new analytics solutions like machine learning. It uses information from production management, control systems, and asset management applications to provide new opportunities to optimize asset availability and operational performance. This optimization goes beyond functional silos and occurs between silos where significant inefficiency, waste, and sometimes dysfunction often reside.

The conference discussions covered the ability to interact with equipment like a variety of devices on a single site, or widely dispersed machines, and how that ability presents new opportunities for industrial companies, utilities, and equipment suppliers. Another key aspect was machine maintenance data and how to effectively collect and standardize it to enable predictive maintenance use cases. Solution providers like MaintenanceX showcased a different approach to CMMS with mobile data collection and consolidation. Participants learned how to make fact-based decisions using reliable information that aligns with the organization’s objectives. Many AI vendors like Molex and Nanoprecise talked about how to ensure the best possible returns on capital investments over the asset lifecycle using AI solutions.

Cybersecurity for Digitalization and Sustainability

AI and IoT technology benefits can be substantial but can quickly get undermined unless companies address the increased risks of serious, costly cyber incidents. Industrial cybersecurity, as expected, was a very popular topic at the conference. New business processes and technologies are rapidly expanding the pathways for attackers to steal information and disrupt operations. At the same time, industrial security teams are struggling to deal with ransomware and sophisticated nation-state attacks. This situation is jeopardizing worker safety, delivery of critical services, and the operational continuity of plants and facilities that fuel profitability. Digitalized organizations need security strategies that monitor, control, and coordinate security across every corporate device, application, system, and network regardless of where it is located.

Many of the cybersecurity sessions as well as vendors like Zededa and Fortinet talked about concepts like Edge security, OT security as well as the infrastructural security that’s needed to secure the whole end-to-end IoT solutions where OT and IT interact. It was clear that this is a continuous journey and that more needs to be done to follow a more standardized approach to security that everyone can benefit from.

Industrial IoT Platforms, Edge Infrastructure, and End Devices

Industrial Edge platforms are emerging as pivotal, value-added components of the Industrial Internet of Things (IIoT) architecture. These platforms add incremental value by functioning not only as the glue linking connected industrial devices to higher-level, performance-enhancing applications but also as the execution environment for the applications themselves. Given the amount of enhancements made in Edge computing, more and more process-heavy applications (including AI and GenAI) can be run on the Edge with instant results applied close to the data source. The outcomes of these Edge solutions can then be sent to the cloud which reduces the amount of data sent to the cloud and also ensures that the data is in the right context.

Many Edge solution vendors including Ignition Edge, HiveMQ Edge, and HighByte Intelligence Hub platform showcased their solution and the role they play in the IIoT data architecture.

Pharma Manufacturing IoT Architecture

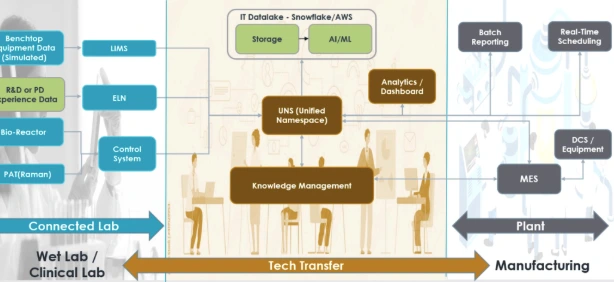

At the conference, talking to customers and other prospects in the Pharma manufacturing space, I gained some unique insights into the world of Pharma IoT architecture (Fig. 2). Pharma presents a very unique perspective on manufacturing where there is a lot of R&D for a drug that is done in a very controlled clinic/wet lab environment which includes some limited manufacturing. Once the R&D is completed, there is a hand-off that happens to the Manufacturing so that the drug could then be mass produced. This manufacturing could be inhouse or done by a Contract Manufacturing company (CMO).

Between the clinic and the manufacturing, there typically is a team that does the knowledge/tech transfer and also helps set up the environment for manufacturing, especially the required architecture and configurations. The job of this delivery/hand-off team is very important as they become the gate keepers that translate the work done in the clinics to ensure that they can seamlessly be mass produced in manufacturing. They are the ones that evaluate new technologies such as Unified Namespace, Analytics, Datalake, etc. on behalf of the organization.

Figure 2: Typical pharma architecture showing the bridge between research and manufacturing. Image source: Zaether

Figure 2: Typical pharma architecture showing the bridge between research and manufacturing. Image source: Zaether

GxP Compliance

One of the industry best practices in Pharma Manufacturing is called GxP which refers to the ‘good practice’ guidelines and regulations created to ensure that food, medical devices, drugs, and other life science products are safe, effective, and usable. The Manufacturing side of Pharma strictly follows that and only works with approved vendors that are compliant with GxP. It's important for IoT vendors to be aware of that and ensure that their product complies with GxP if they want to be part of the manufacturing systems.

Industrial Data Management Enables Industrial AI and Other IIoT Use Cases

Industrial Data Management, which is part of Data Fabric, is a key enabler for Industrial AI and all of the other IIoT use cases. HiveMQ offers an MQTT platform that consists of Edge, Enterprise Broker, Extensions, and Data Hub product suite that enables industrial data management by providing a Unified Namespace which becomes a single source of truth for all industrial contextualized business data for the company. Download HiveMQ and try us out for free.

Ravi Subramanyan

Ravi Subramanyan, Director of Industry Solutions, Manufacturing at HiveMQ, has extensive experience delivering high-quality products and services that have generated revenues and cost savings of over $10B for companies such as Motorola, GE, Bosch, and Weir. Ravi has successfully launched products, established branding, and created product advertisements and marketing campaigns for global and regional business teams.