Digital Transformation in Chemical Manufacturing With UNS, MQTT & Distributed Data Intelligence

The global chemicals digitalization market is projected to grow at a CAGR of 23.1%, reaching around $60.13 billion by 2030. Chemical manufacturing is rapidly embracing digitalization and digital transformation to enhance efficiency, sustainability, compliance, and competitiveness. At the heart of this transformation is the adoption of Industrial IoT (IIoT) solutions, with MQTT-powered Unified Namespace (UNS) playing a crucial role in enabling seamless data integration and real-time communication across various systems and processes within chemical manufacturing environments.

However, achieving true digital transformation requires more than just data connectivity—it demands context-based intelligence. Many chemical manufacturers operate with legacy infrastructure and fragmented data sources, making it difficult to achieve a unified, real-time view of operations. Successfully navigating this transformation requires addressing these barriers while ensuring scalability, security, and regulatory compliance. This is where Distributed Data Intelligence, built on UNS and powered by MQTT, comes into play. With Distributed Data Intelligence, data really does not need to be moved to achieve intelligence. It could just be queried and contextualized based on where it currently resides.

Navigating Data Challenges in Chemical Manufacturing

In one of our earlier whitepapers, Chemical Manufacturing Industry Digitization and our solution page, we discussed some of the key challenges currently impacting the chemical industry, such as:

Data fragmentation and siloed systems

Scalability concerns

Regulatory compliance

Integration of new technologies

These challenges can be effectively addressed by leveraging a Distributed Data Intelligence approach, which enables consistent data organization, facilitates seamless communication between disparate systems, and enhances data analysis and scalability across OT and IT ecosystems while minimizing data movement.

How UNS, MQTT, and Distributed Data Intelligence Transform Chemical Manufacturing

A Distributed Data Intelligence framework, built on a UNS and powered by MQTT, empowers chemical manufacturers to:

Break Down Data Silos: Creating a unified, structured data model.

Enable Real-Time Monitoring and Predictive Analytics: Facilitating immediate detection and response to process deviations while predicting potential failures.

Enhance Regulatory Compliance: Automating reporting, ensuring traceability, and more through centralized data management.

Improve Decision-Making: By transforming raw industrial data into actionable intelligence, chemical manufacturing units can optimize production processes, reduce waste, and improve yield.

Improve Data Quality: By reducing batch variations (via instant feedback loops for process adjustments) and by enhancing predictive quality analytics (through integrating lab results, sensor data, and historical trends).

Promote Sustainable Manufacturing & Energy Efficiency: By optimizing energy consumption (through integrating utility data with process control) and by enabling carbon footprint monitoring for sustainability reporting.

HiveMQ for Digital Transformation

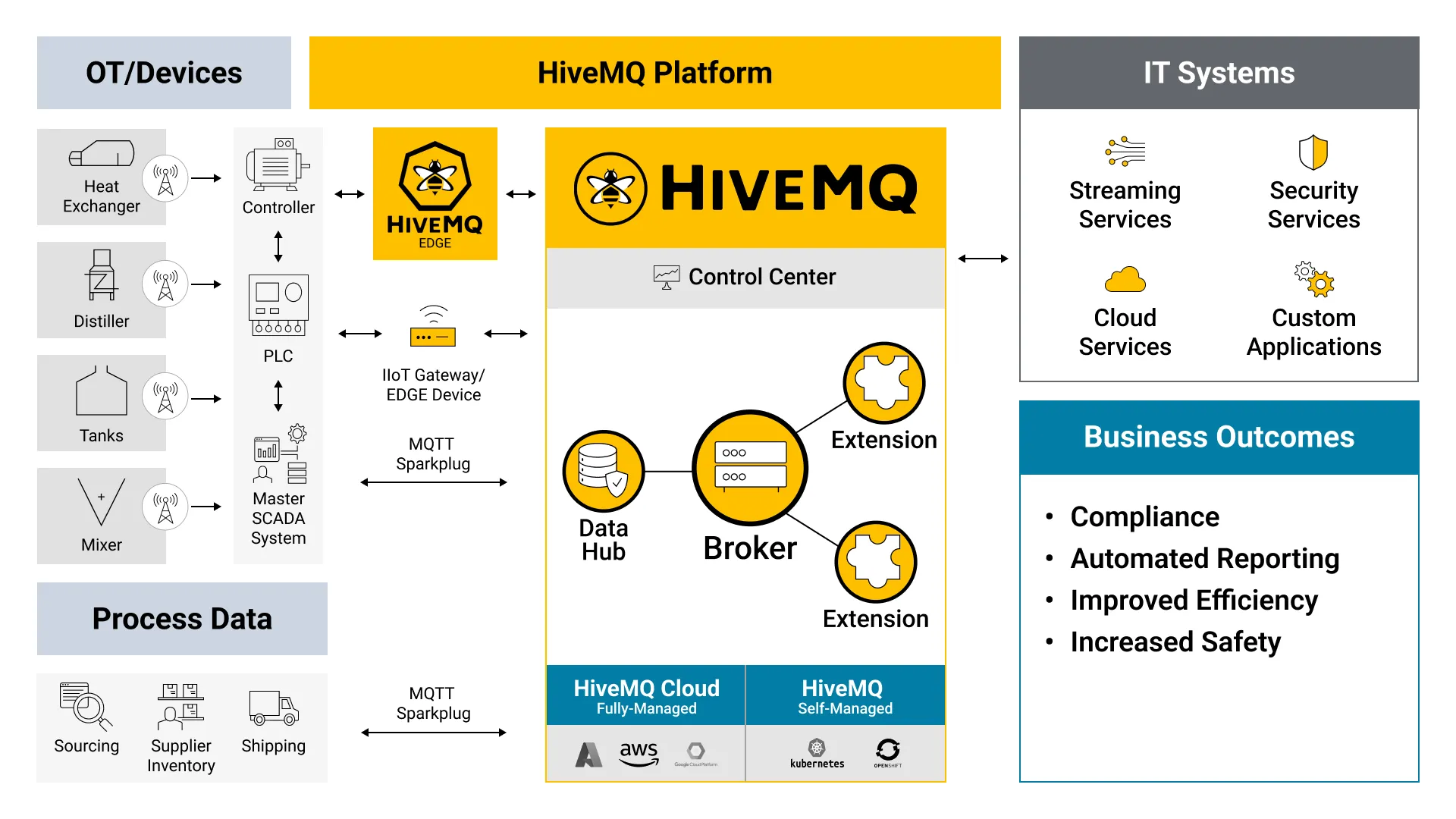

HiveMQ has been at the forefront of helping chemical manufacturers accelerate their digital transformation journeys by enabling seamless, real-time, and secure data flow between OT and IT systems. Our enterprise MQTT platform lays a powerful foundation for chemical manufacturing. It solves data connectivity and interoperability challenges by providing a secure, reliable, and scalable data abstraction layer between OT and IT systems. It also serves as a powerful UNS for all of the contextualized business data, which then enables distributed data computation to power advanced analytics use cases.

Image: Chemical manufacturing typical architecture using HiveMQ MQTT Platform

Image: Chemical manufacturing typical architecture using HiveMQ MQTT Platform

Case in Point: MQTT Benefits in Action

Currenta, a prominent infrastructure manager and service provider for CHEMPARK—one of Europe's largest chemical parks—exemplifies the successful adoption of MQTT in the chemical industry. Facing the challenge of centralizing and enhancing the efficiency of their wastewater testing services, Currenta sought a solution that would streamline operations and support their commitment to safety and sustainability.

By implementing HiveMQ's enterprise-grade MQTT platform, Currenta established seamless communication between their industrial services, plants, and systems. This integration not only reduced network overhead but also enabled the development of new services, such as online sampling devices for CHEMPARK-wide applications.

"As we move towards an increasingly connected industrial landscape, the role of a robust, reliable, and flexible MQTT platform becomes more critical. HiveMQ has proven itself to be that platform for us." – Dr. Jannick Kappelmann, Technical Data Steward at Currenta.

This strategic move allowed Currenta to overcome operational hurdles and drive digital transformation.

Next Steps: Building a Future-Ready Chemical Manufacturing Ecosystem

For chemical manufacturers aiming to adopt MQTT as part of their digital transformation strategy, the following considerations are essential:

Scalability: Ensuring the chosen MQTT platform can handle a large number of devices and high message throughput. For example, large-scale chemical plants often have thousands of sensors generating real-time data. A scalable MQTT-based UNS can ensure uninterrupted communication and data flow across all systems concurrently without straining the infrastructure while having the ability to vertically or horizontally scale as needed. When that UNS is combined with Distributed Data Intelligence, manufacturers can further optimize operations by contextualizing real-time data from these sensors, performing real-time queries, transforming data formats on the fly, and performing historical trend analysis. This allows automated decision-making and process control.

Security: Implementing robust security measures, including authentication, authorization, and encryption, to protect sensitive data. In chemical manufacturing, where intellectual property and process data are critical, a secure MQTT platform ensures that unauthorized access and cyber threats are mitigated. A Distributed Data Intelligence system layered on top of UNS enhances data security by enforcing real-time anomaly detection and adaptive access controls.

Interoperability: Selecting solutions that seamlessly integrate with existing systems and protocols within the manufacturing environment. For instance, a UNS built on MQTT can bridge legacy Distributed Control Systems (DCS) with modern cloud-based analytics, ensuring seamless operations. By incorporating Distributed Data Intelligence, chemical manufacturers can dynamically harmonize data from different systems without necessarily moving data, making cross-platform analytics and enterprise-wide visibility possible.

Conclusion

The fusion of Unified Namespace architecture, MQTT protocol, and Distributed Data Intelligence represents a transformative shift for the chemical industry. As demonstrated by Currenta's experience, using MQTT makes sense for what they are trying to do. To top it all, the technology synergy between MQTT, UNS, and Distributed Data Intelligence not only streamlines operations but also fosters innovation, enhances safety, and ensures compliance with regulatory standards. Chemical manufacturers who adopt these technologies and leverage their synergy will be better equipped to navigate the evolving industrial landscape, gain a competitive edge, and achieve sustainable growth.

HiveMQ Pulse recently launched a next-generation distributed data intelligence platform that transforms unstructured data into actionable insights. It unifies data from edge to cloud within a structured namespace that is automatically discovered, delivering high-throughput, contextualized insights precisely where they have the most impact. Talk to us if you are looking to implement UNS, MQTT, and Distributed Data Intelligence in chemical manufacturing. Or join HiveMQ Pulse private preview to get a glimpse of its transformative powers.

HiveMQ Team

The HiveMQ team loves writing about MQTT, Sparkplug, Industrial IoT, protocols, how to deploy our platform, and more. We focus on industries ranging from energy, to transportation and logistics, to automotive manufacturing. Our experts are here to help, contact us with any questions.