Digital Transformation in Oil & Gas With UNS, MQTT & Distributed Data Intelligence

The Oil & Gas industry is undergoing a seismic shift. As Oil & Gas companies strive to increase efficiency, reduce operational risks, and meet sustainability targets, digital transformation has become a strategic imperative. But unlocking the full potential of digitalization hinges on one critical factor: data. Specifically, the ability to access, manage, and act on IoT data in real time, across vast and often remote operations.

The success of digital transformation depends on removing data silos, modernizing legacy infrastructure, and enabling real-time decision-making across upstream, midstream, and downstream operations. Achieving this calls for embracing a new generation of technologies like MQTT, Unified Namespace (UNS) and Distributed Data Intelligence. In this blog, we explore how these technologies drive digital transformation and operational excellence. Before we explore these technologies, let’s explore the core data challenges that Oil & Gas companies face.

Navigating the Data Challenges in Oil & Gas

The oil and gas industry faces a myriad of data challenges that impede operational efficiency and regulatory compliance. A notable example is a leading upstream exploration and production company operating across the U.S., Egypt, and the UK North Sea. They encountered significant hurdles in collecting and monitoring near real-time data from remote oil fields. The remoteness of these sites, coupled with limited bandwidth and unreliable connectivity, made continuous on-site human presence challenging. Moreover, to remain compliant with the Environmental Protection Agency (EPA), the company needed an effective way to monitor these sites and promptly address potential failures. Their existing Modbus-based communication infrastructure was not scalable and incurred prohibitive costs, with data transmission delays of 5 to 10 minutes—an unacceptable lag for critical operations.

This real-world example highlights a broader pattern of similar and other challenges faced across the oil and gas industry, including:

Fragmented Systems: Multiple generations of SCADA, PLCs, and historians lead to siloed data.

Remote Locations: Connectivity issues in offshore rigs, pipelines, and remote wells limit real-time visibility.

High Latency: Traditional polling-based architectures can’t keep up with real-time monitoring demands.

Lack of Standardization: Disparate naming conventions and inconsistent data structures hinder interoperability.

Without a scalable architecture for collecting, contextualizing, and distributing industrial data, these challenges hinder digital transformation efforts, limit the return on IIoT investments, and expose operations to inefficiencies and risks. However, MQTT, Unified Namespace, and distributed data intelligence offer a path forward. Let’s explore each of these.

MQTT Protocol

MQTT is a lightweight, publish-subscribe messaging protocol optimized for high-latency and unreliable networks, common in remote oil and gas operations. Its efficient bandwidth utilization and minimal overhead make it ideal for real-time data transmission from field devices to central systems, ensuring timely and reliable communication. It needs an MQTT broker to communicate between devices. If you are new to MQTT, read MQTT Essentials.

Unified Namespace (UNS)

UNS provides a centralized, structured, and hierarchical data model that integrates diverse data sources, including SCADA systems, PLCs, and historians. This unified approach facilitates seamless data access and interoperability across various operational domains, enhancing situational awareness and decision-making. To learn more about Unified Namespace, read our UNS Essentials.

Distributed Data Intelligence

By deploying data processing capabilities at the edge, organizations can perform real-time analytics and decision-making closer to the data source. This approach reduces latency, minimizes bandwidth consumption, and enhances the responsiveness of control systems, leading to improved operational efficiency and safety.

Together, these concepts and technologies form the backbone of a resilient digital ecosystem. MQTT provides the connectivity layer for efficient and reliable data transmission; UNS ensures that data is structured and contextualized across systems; and distributed data intelligence enables edge-to-cloud data transformation.

HiveMQ platform, built on MQTT and aligned with UNS principles, and enriched by distributed data intelligence capabilities, provides a scalable, secure, and observable data streaming platform. This unified approach ensures not only reliable connectivity and contextualized data through a Unified Namespace, but also intelligent processing at the edge.

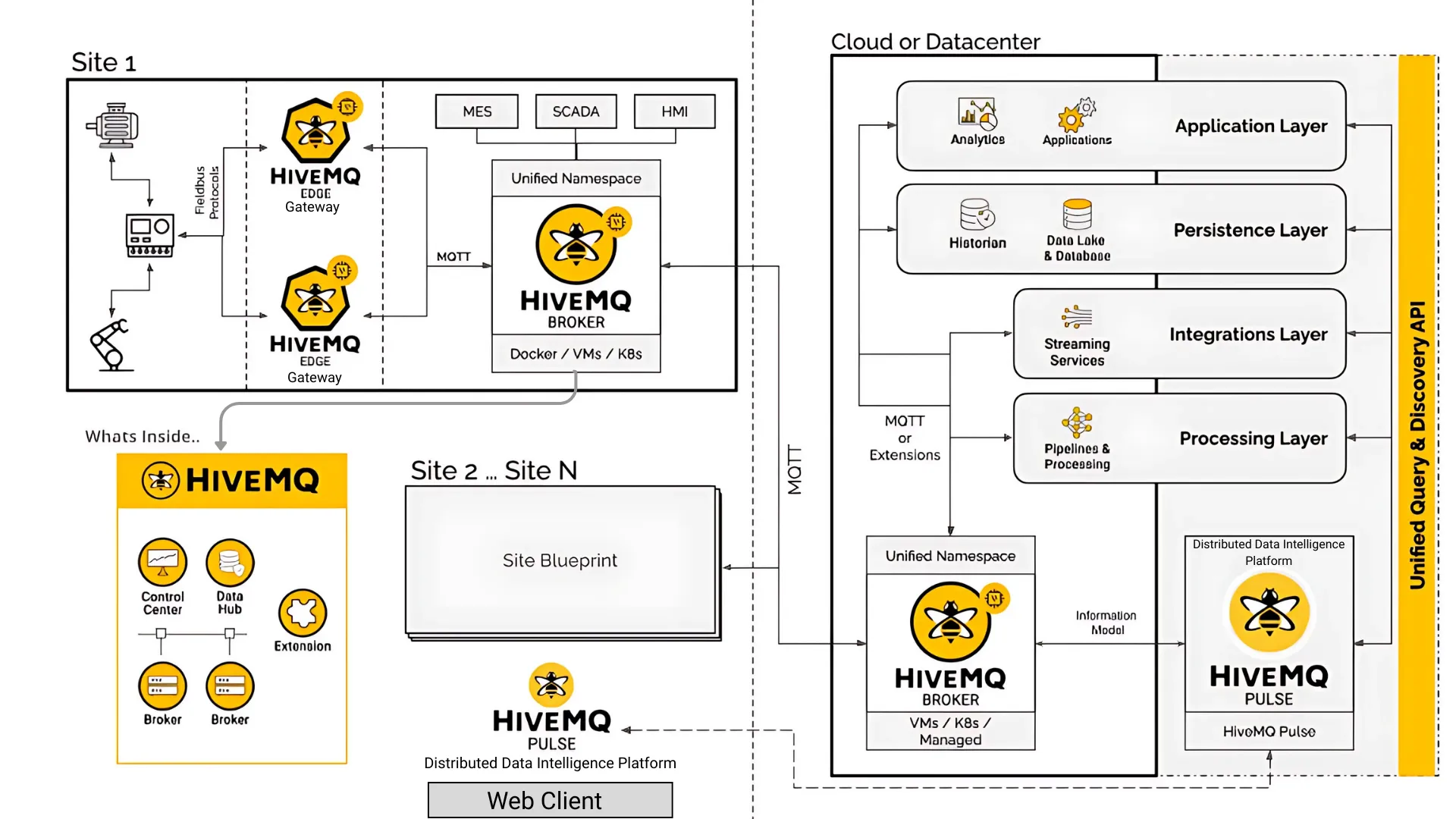

Here’s a top-level architecture diagram of how MQTT, UNS, and a distributed data intelligence platform come together to enable use cases for digital transformation with HiveMQ platform.

This convergence of technologies not only simplifies integration across the industrial landscape but also powers transformative use cases—from predictive maintenance and process optimization to enhanced asset performance and real-time control across the oil and gas value chain.

This convergence of technologies not only simplifies integration across the industrial landscape but also powers transformative use cases—from predictive maintenance and process optimization to enhanced asset performance and real-time control across the oil and gas value chain.

Now that we've seen how MQTT, UNS, and distributed data intelligence come together to power a resilient digital foundation, let’s dive into some of the key use cases that demonstrate their impact across the oil and gas value chain.

Real-World Use Cases of MQTT, UNS & Distributed Intelligence in Oil & Gas

In Oil & Gas, whether upstream, midstream, or downstream, the goal is the same: streamline operations, minimize downtime, and unlock insights from field data that was once too fragmented, delayed, or inaccessible to be useful. Let’s touch upon some of the key use cases.

Upstream – Exploration & Production

Remote Monitoring and Control

In the upstream segment, assets are often in hard-to-reach places, such as offshore rigs, remote well pads, or vast desert basins. Reliable data transmission from these locations is critical. MQTT ensures resilient, low-bandwidth communication between field sensors and control systems. Even with unstable satellite links, operators receive timely updates that enable proactive decision-making from centralized control centers. When paired with a Unified Namespace, this data is structured and made accessible in real time, giving teams a unified view of operations. Additionally, distributed data intelligence allows edge-based processing of sensor data, enabling immediate response and autonomous control even when connectivity is limited.

Predictive Maintenance

Drilling equipment generates a wealth of telemetry, such as vibration, pressure, and temperature. By using MQTT’s push-based model, maintenance teams can reduce downtime and avoid expensive, unplanned outages. With a Unified Namespace in place, all telemetry data is contextualized and accessible across teams, enabling a consistent and comprehensive view of equipment health. Distributed data intelligence further enhances this by enabling local anomaly detection and alerting at the edge, allowing quicker response times and reducing dependency on centralized systems.

Midstream – Transportation & Storage

Optimized Distribution

Efficient midstream operations hinge on real-time awareness. With MQTT, logistics systems get a steady stream of tank levels, flow rates, and pump conditions. This allows for optimized scheduling of truck routes, pipeline flows, and storage capacity, thus reducing waste and improving delivery predictability. A Unified Namespace helps harmonize and contextualize data from different assets and facilities, giving planners and operators a holistic view of operations. Additionally, distributed data intelligence enables processing and filtering of data at the edge, ensuring only the most relevant, high-value information is transmitted, thus enhancing decision-making and conserving bandwidth in complex, distributed environments.

Pipeline Monitoring & Leak Detection

Safety and compliance are paramount in Oil & Gas setups. Pressure sensors, flow meters, and acoustic monitors feed continuous data streams into monitoring systems. An enterprise MQTT broker ensures that anomalies are detected and alerts are delivered instantly, even across distributed geographies. This supports faster incident response and minimizes environmental and financial impact. With a Unified Namespace, these sensor data streams are normalized and contextualized, enabling rapid cross-team access and understanding. Distributed data intelligence further enhances safety by analyzing patterns locally at the edge, triggering instant alerts and localized responses even before the data reaches central monitoring hubs.

Downstream – Refining & Distribution

Asset Performance Management

Refineries rely on hundreds of interconnected systems, from compressors to reactors to heat exchangers. With an MQTT broker and a Unified Namespace, teams can view asset performance holistically. Data is aggregated, normalized, and made context-rich, enabling better decision-making on maintenance and CAPEX planning. Distributed data intelligence complements this by enabling local analysis of equipment data at the edge, allowing for faster fault detection, real-time condition monitoring, and reduced strain on central systems, thus ensuring performance issues are addressed proactively rather than reactively.

Process Optimization & Control

Whether it’s managing catalytic cracking temperatures or adjusting chemical dosing rates, milliseconds matter in oil & gas setups. A Unified Namespace, built on top of MQTT, helps deliver critical process data in real time to control systems, enabling tight process control and consistent product quality. This improves yield, reduces waste, and supports continuous improvement programs. With a Unified Namespace, all process data is contextualized and accessible in one place, helping teams detect inefficiencies and fine-tune parameters quickly. Distributed data intelligence enhances this capability by enabling ultra-low-latency analysis at the edge, allowing systems to self-correct or raise alerts instantly based on local conditions, thus maximizing responsiveness and maintaining optimal performance.

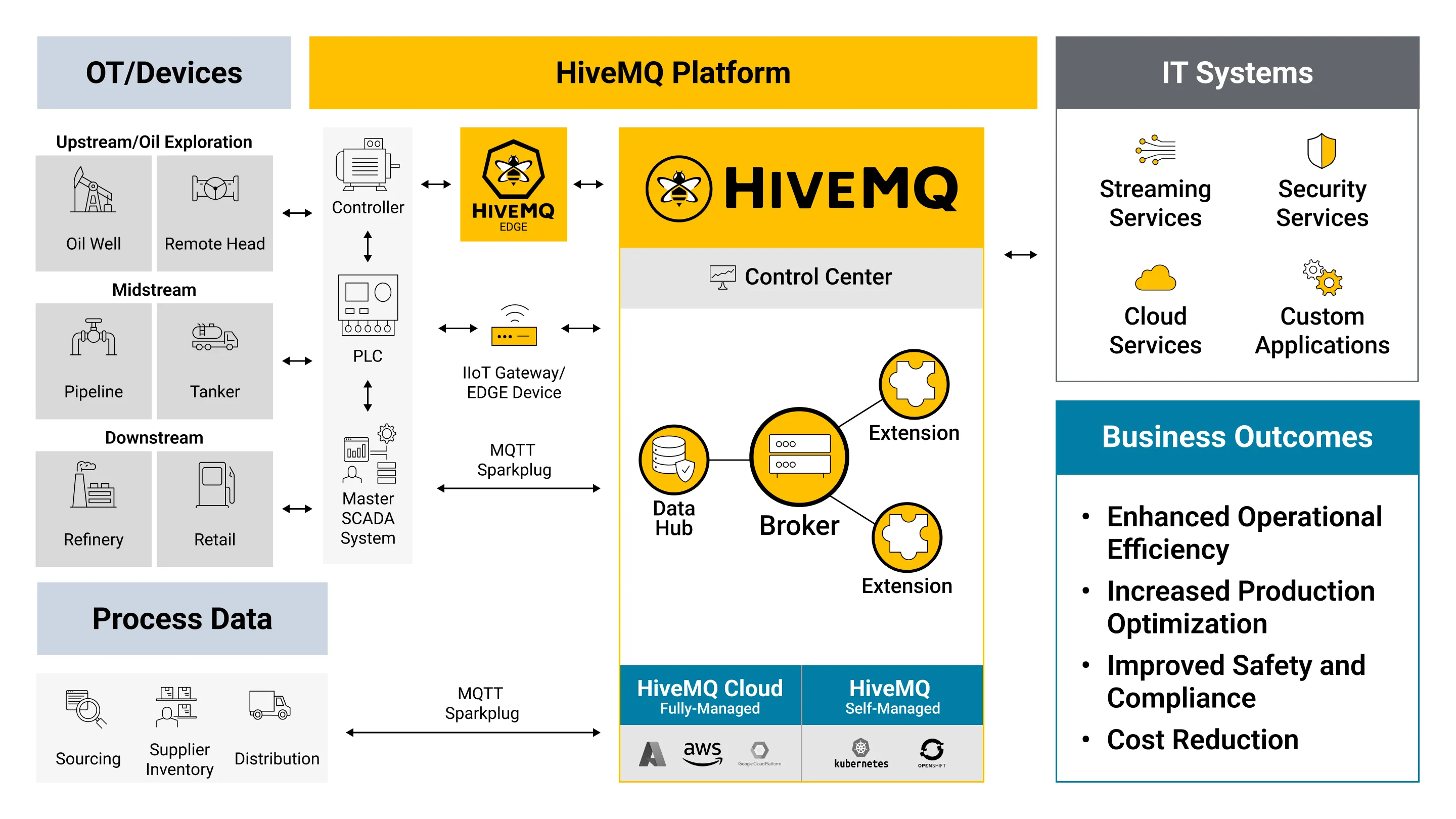

As briefly discussed earlier, the HiveMQ IoT Data Streaming Platform brings these technologies together in one unified, enterprise-ready solution. By combining the power of MQTT, Unified Namespace, and distributed data intelligence, HiveMQ enables oil and gas companies to achieve true IT/OT convergence. Let’s dive into how HiveMQ brings value on the top. Let’s have a deeper look at the HiveMQ Platform and how it enables digital transformation for oil and gas.

MQTT-Powered HiveMQ IoT Data Streaming Platform for Oil & Gas

HiveMQ is purpose-built to serve as the central nervous system for oil and gas data streams. As an enterprise-grade IoT Data Streaming platform, HiveMQ provides:

Reliable Connectivity: Designed to work seamlessly in remote and rugged conditions.

Scalability: Supports millions of concurrent MQTT connections across upstream, midstream, and downstream assets.

Security: TLS encryption, access control, and enterprise-grade authentication to protect sensitive operational data.

Interoperability: Integrates with OT systems, cloud platforms, data lakes, and analytics tools.

Observability: Built-in metrics, logging, and dashboards for end-to-end monitoring and troubleshooting.

HiveMQ brings several critical advantages to oil and gas environments, particularly in challenging operational contexts. Its resilience ensures uninterrupted data delivery even in remote and connectivity-challenged locations. Efficiency comes from MQTT’s lightweight publish/subscribe model, which minimizes bandwidth and compute usage. The platform integrates cleanly with a Unified Namespace to provide transparency, allowing IT and OT teams to access structured, contextualized data from across the organization. Speed is another key benefit—HiveMQ ensures that real-time insights flow freely for quick decision-making and emergency response. Lastly, HiveMQ is built with a future-proof architecture that embraces open standards and supports flexible deployment options, from on-premise setups to edge computing and cloud integrations.

Your Data, Your Advantage with HiveMQ

Digital transformation in oil and gas is about more than deploying technology. It’s about ensuring the right data reaches the right people at the right time. HiveMQ, built on MQTT and aligned with UNS principles, and enriched by distributed data intelligence capabilities, provides a scalable, secure, and observable data streaming platform. This unified approach ensures not only reliable connectivity and contextualized data through a Unified Namespace, but also intelligent processing at the edge. The result is a system that empowers real-time insights, supports autonomous responses, and delivers future-proof infrastructure for modernizing operations, reducing risks, and maximizing operational agility.

Ready to transform your oil and gas operations? Contact our team to learn how HiveMQ can help.

HiveMQ Team

The HiveMQ team loves writing about MQTT, Sparkplug, Industrial IoT, protocols, how to deploy our platform, and more. We focus on industries ranging from energy, to transportation and logistics, to automotive manufacturing. Our experts are here to help, contact us with any questions.