Digital Transformation in Pharma Manufacturing With UNS, MQTT & Distributed Data Intelligence

The pharmaceutical manufacturing industry is evolving rapidly, propelled by the adoption of cutting-edge digital technologies—a shift commonly known as Pharma 4.0. However, achieving true digital transformation goes beyond merely implementing new tools; it hinges on effectively leveraging data. Many pharmaceutical manufacturers grapple with outdated infrastructure and disjointed data systems, making it challenging to gain a comprehensive, real-time operational perspective.

To truly transform data management, organizations need not only connectivity but also intelligent context. This is where Unified Namespace (UNS), the MQTT protocol, and Distributed Data Intelligence become crucial. These technologies help manufacturers break down silos, enabling a seamless, data-driven approach that optimizes compliance, efficiency, and innovation.

Mitigating Data Struggles of Pharma Manufacturing

The pharmaceutical world is highly regulated, and compliance management is both time-consuming and costly. In addition, they also have to deal with GXP guidelines. Non-compliance can lead to significant fines or legal actions from organizations such as the FDA and the European Medical Agency. For instance, the FDA's 21 CFR Part 11 mandates that electronic records of all drug manufacturing data be available in raw, uninterpreted format for at least seven years for audits.

To navigate these challenges, pharma manufacturers are increasingly turning to digital technologies and automation. This approach, termed Pharma 4.0, involves the use of advanced technologies such as artificial intelligence (AI), Generative AI, machine learning, robotics, and IIoT to improve operations and ensure compliance.

The Role of UNS, MQTT, and Distributed Data Intelligence in Digital Transformation

Achieving true digital transformation requires more than just data connectivity—it demands context-based intelligence. Many pharma manufacturers operate with legacy infrastructure and fragmented data sources, making it difficult to achieve a unified, real-time view of operations. Successfully navigating this transformation requires addressing these barriers while ensuring scalability, security, and regulatory compliance.

This is where Distributed Data Intelligence, built on UNS and powered by MQTT, plays a crucial role. Traditional data management approaches rely on transferring vast amounts of information to centralized systems for processing, which introduces latency, increases storage demands, and complicates regulatory compliance. In contrast, Distributed Data Intelligence enables real-time insights by querying and contextualizing data at its source, eliminating unnecessary data movement while maintaining integrity and security.

Unified Namespace (UNS): Acting as an enterprise-wide data framework, UNS structures and organizes information across IT and OT environments, creating a single source of truth. By standardizing data access, eliminating silos, and contextualizing data, it enables seamless interoperability between disparate systems, ensuring real-time visibility and actionable insights.

MQTT Protocol: As an event-driven, lightweight messaging protocol, MQTT ensures secure, efficient, and scalable data exchange across distributed networks. Its publish-subscribe model minimizes bandwidth consumption, making it ideal for low-latency, high-frequency data transmission in pharmaceutical manufacturing environments.

Distributed Data Intelligence: Instead of relying on centralized processing all the time, Distributed Data Intelligence leverages local data processing, data querying through standard interfaces to extract meaning from data where it is generated. This not only reduces the complexity of data pipelines but also enhances responsiveness, reduces data costs, and ensures compliance with industry regulations while supporting predictive and prescriptive decision-making.

By combining these technologies, pharmaceutical manufacturers can move beyond fragmented, reactive operations to a connected, intelligent, and resilient data-driven ecosystem that improves compliance, efficiency, and innovation.

MQTT-Powered HiveMQ IoT Data Streaming Platform for Pharma 4.0

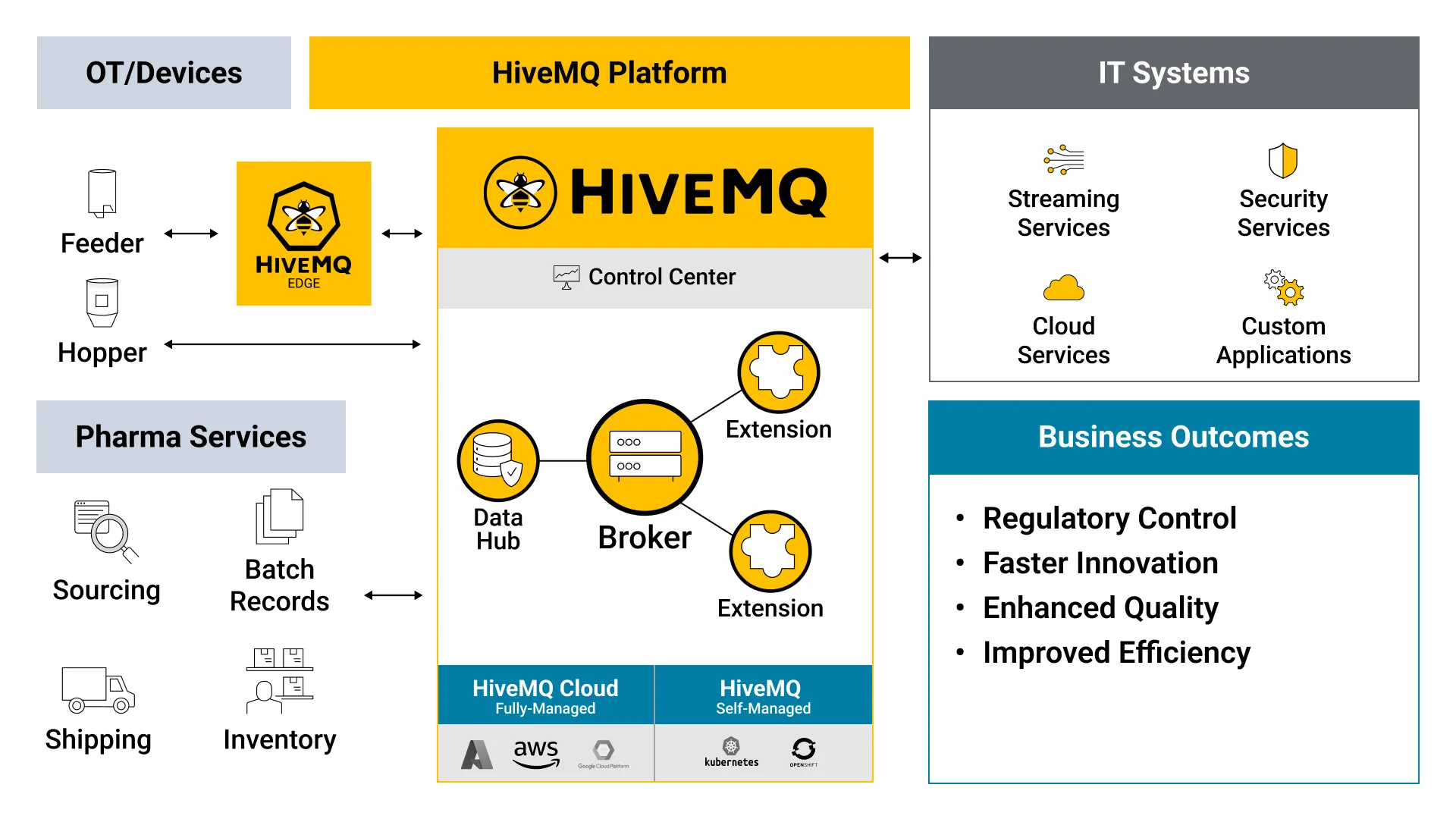

A pivotal component of this digital transformation is the implementation of robust IoT data streaming platforms that facilitate seamless communication between Operational Technology (OT) and Information Technology (IT) systems. The HiveMQ MQTT platform exemplifies such a solution, offering a secure, reliable, and scalable data abstraction layer tailored for the pharmaceutical industry.

Key Benefits of HiveMQ for Pharma Manufacturing

Business-Critical Reliability: HiveMQ ensures 24/7 operation of mission-critical systems with zero message loss, supported by redundant clustering technology.

End-to-End Security: The platform offers configurable security controls safeguarding applications and data to meet the highest security standards.

Scalability to Support Growth: Designed for linear scalability, HiveMQ allows seamless addition of sites and can handle millions of connected devices, accommodating organizational growth effortlessly.

Unified Data Management: HiveMQ Pulse catalogs, transforms, and governs data within a Unified Namespace, ensuring interoperability and standardization across OT and IT systems. This unified approach facilitates seamless data integration and enhances decision-making processes.

Real-Time Actionable Insights: By processing and contextualizing data in motion, HiveMQ Pulse reduces delays, improves efficiency, minimizes downtime, and drives faster, data-driven decisions. This capability is crucial for maintaining high-quality standards and responding promptly to operational changes.

Distributed Data Intelligence: HiveMQ Pulse integrates a calculation engine and AI/ML models at the edge, reducing latency and enabling real-time automation. This Distributed Data Intelligence enhances predictions and optimizes workflows, leading to more responsive and agile manufacturing processes.

Building upon the robust capabilities of the HiveMQ MQTT platform, HiveMQ Pulse offers a next-generation Distributed Data Intelligence solution designed to transform unstructured data into actionable insights. For pharmaceutical manufacturers, this means enhanced data management, real-time analytics, and improved operational efficiency.

Case Study: Leading Pharmaceutical Manufacturer's Digital Transformation Story

A prominent pharmaceutical company with 15 manufacturing sites worldwide sought to modernize its operations to enhance efficiency, quality, and innovation while ensuring compliance with regulatory mandates. By implementing HiveMQ's platform, the company achieved:

Global Deployment: HiveMQ was successfully deployed across all 15 factories, ensuring consistent data management practices.

High Reliability: The company experienced 99.999% uptime with zero data loss, crucial for maintaining compliance and operational continuity.

Regulatory Adherence: Automated data collection and storage facilitated compliance with regulations requiring long-term data retention, simplifying audit processes.

This transformation not only ensured regulatory compliance but also enhanced operational efficiency and provided peace of mind for factory operators.

Conclusion

The integration of UNS, MQTT, and Distributed Data Intelligence is pivotal in the digital transformation of pharmaceutical manufacturing. Platforms like HiveMQ enable organizations to overcome traditional challenges—ensuring regulatory compliance, fostering innovation, enhancing product quality, and improving operational efficiency. Adopting these technologies positions pharmaceutical manufacturers to thrive in the evolving landscape of Pharma 4.0.

Join the waiting list for HiveMQ Pulse private preview to get a glimpse of its transformative powers. Even better, talk to us if you are looking to implement UNS, MQTT, and Distributed Data Intelligence in pharma manufacturing.

HiveMQ Team

The HiveMQ team loves writing about MQTT, Sparkplug, Industrial IoT, protocols, how to deploy our platform, and more. We focus on industries ranging from energy, to transportation and logistics, to automotive manufacturing. Our experts are here to help, contact us with any questions.