How to Integrate Manufacturing Shop-Floor Data into UNS

Data has become essential for driving efficiency, innovation, and competitiveness. Yet, industry professionals often struggle to determine which shop-floor data to integrate into the Unified Namespace (UNS). This article explores the key events crucial for data collection and how they contribute to a more efficient, insightful manufacturing process.

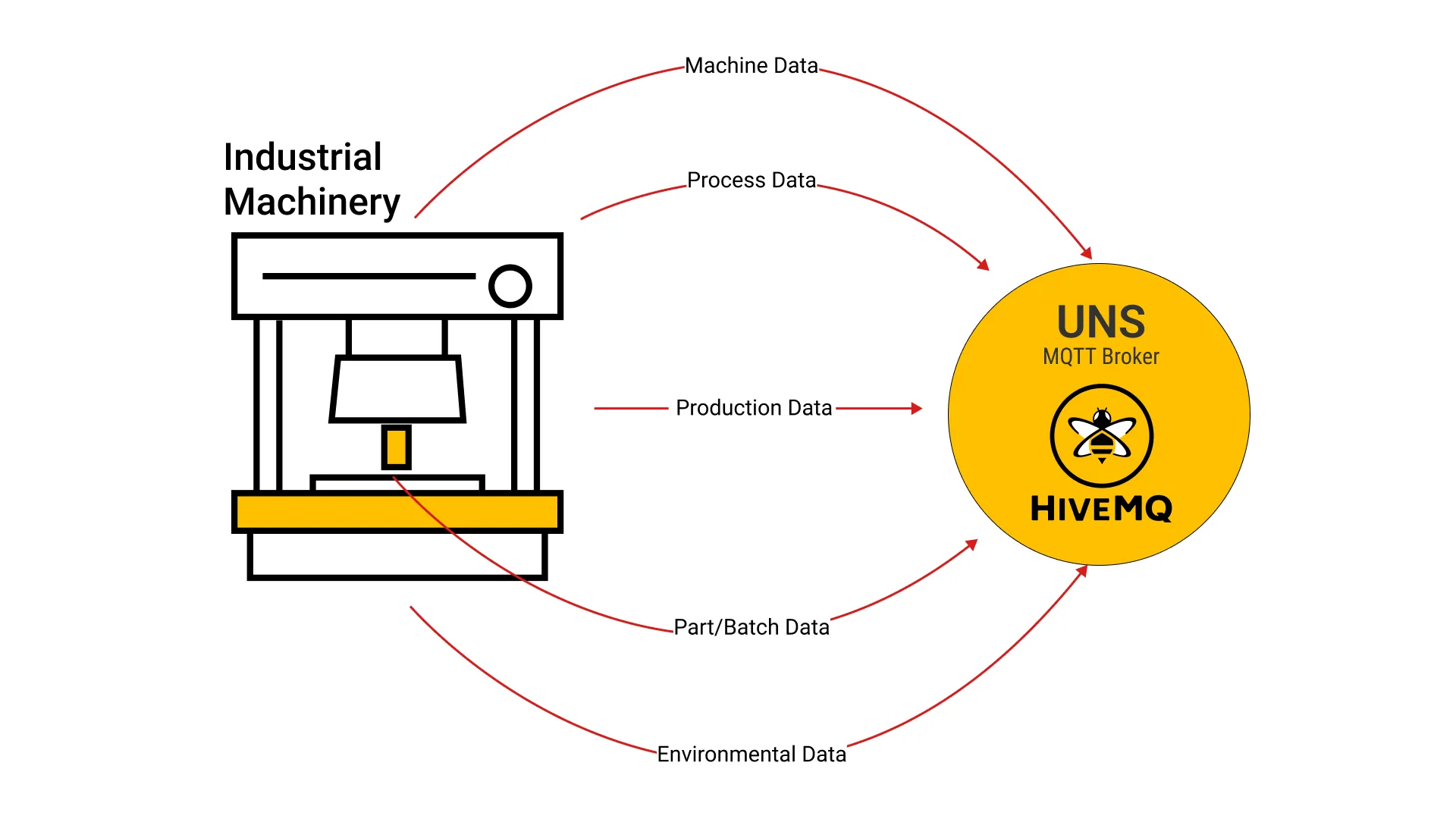

The Unified Namespace (UNS) acts as a centralized repository—a single source of truth—for all operational data within a manufacturing ecosystem. It functions as a real-time data broker using an MQTT data layer, gathering information from various sources across the Controls, Operations, and Business domains of a manufacturing organization. In this article, we will concentrate on integrating data from shop-floor equipment. Let’s examine the different types of data involved.

Production Operations Data

Production operations data captures the core activities and performance metrics of the manufacturing process. This data is fundamental for understanding how well the production line is performing and identifying areas for improvement. Key events under this category include:

Production Cycle Events

These events record the completion of individual production cycles. Each cycle can provide insights into the time taken for production, resource utilization, and potential bottlenecks. By monitoring production cycles, manufacturers can optimize scheduling, reduce waste, and improve overall throughput.

Machine Downtime Events

Machine downtime is a critical metric that directly impacts productivity and profitability. Downtime events can be scheduled, such as for maintenance, or unscheduled due to malfunctions or operator errors. Capturing these events helps in:

Identifying Patterns: Recognizing recurring issues that cause downtime.

Predictive Maintenance: Anticipating equipment failures before they occur.

Resource Allocation: Adjusting manpower and machine availability to minimize disruption.

Machine Starvation Events

Machine starvation occurs when a machine is idle because it lacks the necessary inputs to continue production. This could be due to supply chain issues, logistical errors, or upstream production delays. Recording starvation events enables:

Supply Chain Optimization: Identifying and addressing supply bottlenecks.

Process Synchronization: Ensuring that all parts of the production line are adequately supplied.

Cost Reduction: Minimizing idle time reduces operational costs.

Sensor Data

Sensors play a vital role in modern manufacturing by providing real-time data on various physical parameters. This information is crucial for maintaining equipment health and ensuring product quality. Key sensor data examples include:

Coolant Temperatures

Monitoring coolant temperatures is essential for machines that rely on cooling systems to operate effectively. Abnormal temperatures can indicate system failures or inefficiencies, leading to:

Preventive Actions: Adjusting coolant levels or fixing leaks.

Quality Assurance: Ensuring that products are manufactured under optimal conditions.

Power Usage

Tracking power consumption helps understand the energy efficiency of machines. Excessive power usage can signal mechanical issues or the need for equipment upgrades. Benefits include:

Energy Savings: Identifying high-consumption areas to reduce costs.

Environmental Impact: Lowering the carbon footprint of the manufacturing process.

Heat Treat Temperature/Energy

For heat treatment processes, maintaining precise temperatures is critical. Deviations can affect material properties and product quality. Monitoring these parameters ensures:

Product Consistency: Achieving the desired material characteristics.

Process Compliance: Meeting industry standards and regulations.

Vibration Levels

Excessive vibration can be a precursor to mechanical failures. Sensors that track vibration levels help in:

Early Detection: Identifying issues before they lead to equipment breakdown.

Maintenance Scheduling: Planning repairs during non-peak hours to minimize disruption.

Motor Current and Temperature

Monitoring motor current and temperature provides insights into the operational load and health of motors. Abnormal readings can indicate overloads or cooling issues, leading to:

Equipment Protection: Preventing damage due to overheating or electrical faults.

Efficiency Optimization: Ensuring motors operate within optimal parameters.

Part/Batch Data

Part and batch data focus on the specifics of individual units or groups of products moving through the manufacturing process. This data is essential for traceability and quality control.

Quality Measurement Events

Recording quality measurements at various stages allows manufacturers to:

Ensure Compliance: Meeting product specifications and regulatory requirements.

Identify Defects: Quickly detecting and addressing quality issues.

Continuous Improvement: Analyzing trends to improve processes and products.

Part/Batch Machine Change Events

These events occur when there is a change in machine settings for different parts or batches. Tracking these changes helps in:

Configuration Management: Keeping accurate records of machine settings for each product.

Error Reduction: Minimizing the risk of incorrect settings leading to defective products.

Audit Trails: Providing documentation for compliance and quality assurance purposes.

Machine Data

Machine data encompasses the status, performance, and configuration of manufacturing equipment. This information is crucial for maintaining operational efficiency and responding promptly to issues.

Machine State Change Events

These events track transitions between different machine states, such as from idle to active or from maintenance to operational. Monitoring state changes allows for:

Operational Awareness: Understanding machine availability and readiness.

Workflow Optimization: Adjusting schedules based on machine status.

Downtime Reduction: Quickly responding to unexpected state changes.

Machine Alarm Events

Alarms are triggered by predefined conditions that require immediate attention. Capturing alarm events is vital for:

Rapid Response: Addressing issues before they escalate.

Safety Compliance: Ensuring that safety protocols are followed.

Incident Analysis: Investigating causes to prevent future occurrences.

Configuration Change Events

Recording when and how machine configurations are altered is essential for:

Change Management: Tracking adjustments to settings and their impacts.

Quality Assurance: Ensuring that configuration changes do not adversely affect product quality.

Regulatory Compliance: Maintaining records required for audits and certifications.

Environmental Data

The environment in which manufacturing takes place can significantly impact both machinery and product quality. Monitoring environmental factors helps in maintaining optimal conditions.

Room Temperature

Fluctuations in ambient temperature can affect machine performance and material properties. Keeping track of room temperature allows for:

Climate Control: Adjusting HVAC systems to maintain stable conditions.

Product Integrity: Ensuring that temperature-sensitive processes are not compromised.

Energy Efficiency: Optimizing heating and cooling to reduce costs.

Humidity Levels

Humidity can influence processes such as painting, coating, and electronics manufacturing. Monitoring humidity levels aids in:

Quality Control: Preventing defects caused by moisture.

Equipment Protection: Reducing corrosion and electrical issues.

Process Optimization: Adjusting processes based on current humidity conditions.

The Power of Shop-Floor Data Integration with UNS

Collecting and integrating all these diverse data points into the Unified Namespace presents unique opportunities to identify patterns and correlations that were previously undetectable. By leveraging this data, manufacturers can:

Enhance Predictive Analytics: Use historical and real-time data to forecast equipment failures and maintenance needs.

Improve Decision-Making: Access to comprehensive data enables informed decisions that enhance both productivity and quality.

Optimize Operations: Identify inefficiencies across the production line and implement targeted improvements.

Foster Innovation: Uncover insights that lead to developing new products or processes.

The manufacturing environment is a complex system where numerous factors interact simultaneously, making it essential to understand these interactions to effectively address various challenges. For example, analyzing machine starvation events alongside supply data can strengthen supply chain resilience against disruptions. Correlating quality measurement events with environmental data helps identify the root causes of quality variability, leading to better quality control. Furthermore, monitoring machine alarms and state changes allows for proactive risk management, enhancing both safety and reliability within operations. By comprehensively integrating and analyzing shop-floor data, manufacturers can navigate these complexities and maintain a competitive edge.

Conclusion

Incorporating shop-floor events into the Unified Namespace is not just about data collection; it's about transforming that data into actionable insights. By systematically capturing production operations data, sensor readings, part and batch information, machine statuses, and environmental conditions, manufacturers can unlock a deeper understanding of their processes.

This comprehensive approach enables organizations to identify previously hidden patterns, optimize operations, and tackle complex challenges with confidence. In an era where data-driven decision-making is paramount, embracing these practices sets the foundation for sustained success and innovation in the manufacturing industry.

Kudzai Manditereza

Kudzai is a tech influencer and electronic engineer based in Germany. As a Sr. Industry Solutions Advocate at HiveMQ, he helps developers and architects adopt MQTT and HiveMQ for their IIoT projects. Kudzai runs a popular YouTube channel focused on IIoT and Smart Manufacturing technologies and he has been recognized as one of the Top 100 global influencers talking about Industry 4.0 online.