Preventing Supply Chain Disruptions in Automotive Manufacturing

In the automotive manufacturing industry, the prompt delivery of materials is crucial for keeping production running smoothly. Supply chain disruptions such as short-shipped material, low inventory levels, and quality control problems lead to manufacturing disruptions and ultimately money lost. As a result, plant logistics managers and plant production managers must strive to keep the supply chain moving to maintain quality and on-time delivery in the manufacturing process.

The good news is, with the right technology tools, you can prevent supply chain hiccups from turning into manufacturing downtime. Let’s discuss the challenges in modern automotive manufacturing and how HiveMQ’s centralized MQTT Platform provides an end-to-end solution that helps you stay proactive instead of reactive.

Automotive Manufacturing Supply Chain Challenges

Imagine the frustration of expecting a shipment of 500 crucial parts, only to find that 200 have arrived, which will ultimately cause line stoppages and inventory crises. This is a common pain point for automotive manufacturers, where disruptions in the supply chain can quickly snowball. The problem is not only that the shipment was short, but not knowing until the shipment arrives and is unloaded from the truck. By that point it is too late to make an adjustment and the production line will go down two days later when materials run out.

Most manufacturers simply don’t have this kind of visibility into their supply chain and logistics, for various reasons. They don’t have an Industrial IoT solution in place to connect all assets, track them in real-time, and take actions based on that intelligence. They rely on suppliers in remote areas with limited internet connectivity, making it difficult to track shipments and receive timely updates on critical logistics information.

The traditional approach of reacting to issues as they arise is extremely costly and no longer sufficient, so automotive manufacturers are looking to build the right technology infrastructure to overcome these challenges and get the right information to the right person at the right time to be proactive and avoid downtime or quality issues.

Achieving End-to-End Visibility

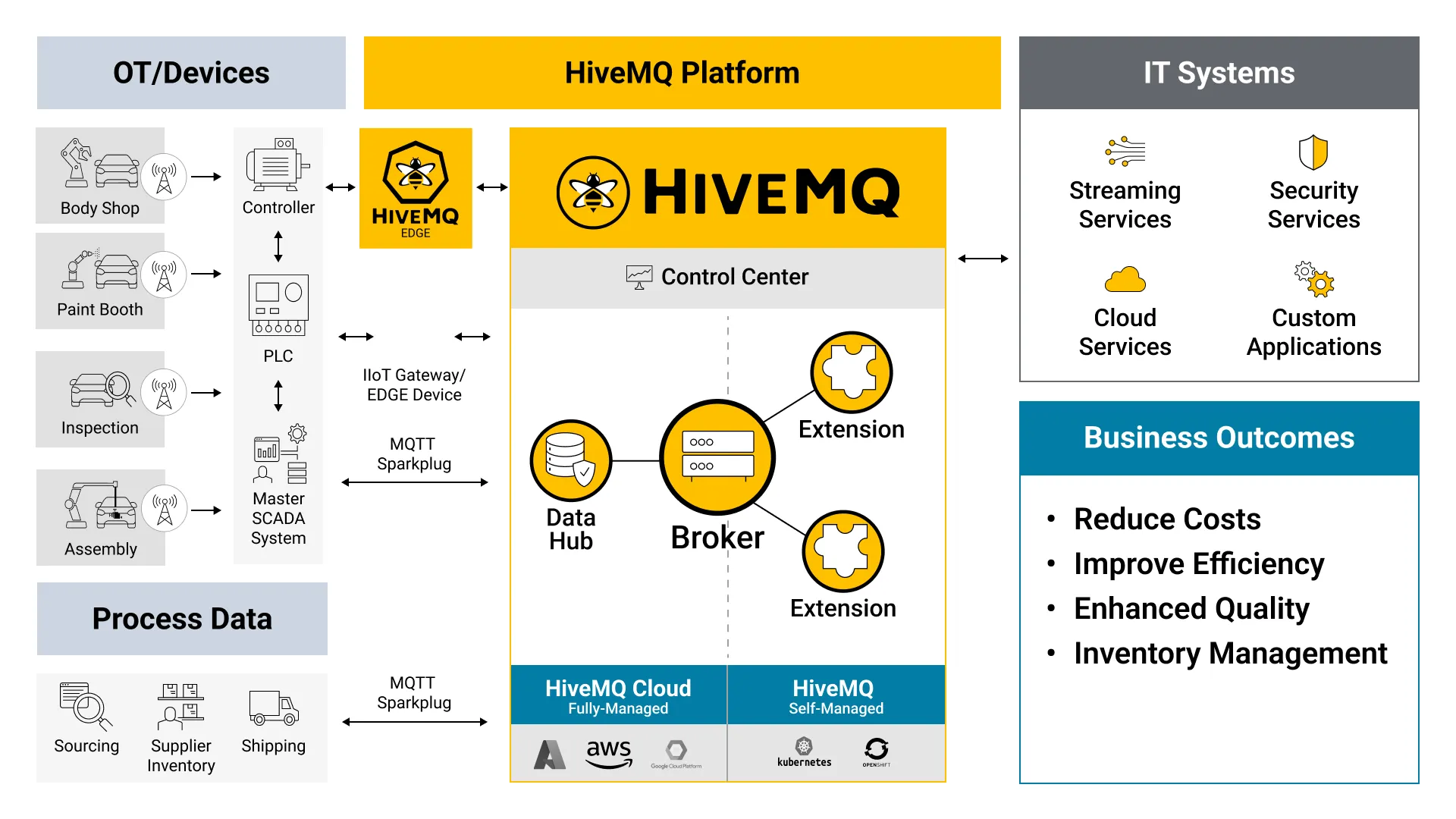

Enter the solution. HiveMQ provides an enterprise MQTT platform that helps in creating a secure, reliable, and scalable data abstraction layer between OT and IT systems. A centralized broker seamlessly connects various systems such as Transportation Management, Warehouse Management, and internal manufacturing databases. By integrating these systems using MQTT, the entire supply chain and manufacturing process become interconnected and accessible in real-time.

How It Works:

End-to-End Visibility: From the moment materials leave the supplier's dock to their integration into the assembly line and beyond, HiveMQ provides an end-to-end story. Real-time tracking ensures that each step is monitored and any deviations are immediately flagged.

Automatic Alerts: Short shipments or discrepancies in received materials trigger automatic alerts, preventing issues from going unnoticed until inventory levels turn critical. This proactive approach is vital for maintaining production numbers and efficiency ratings.

Low-Bandwidth: In regions with low internet connectivity, MQTT's low bandwidth and small packet size become crucial. This ensures that even in desolate areas, real-time data messaging remains possible.

Predictive Analytics: A centralized dashboard, powered by analytics tools like Grafana or a cloud analytics tool, consolidates data from the MQTT broker. This dashboard provides actionable insights into production lines, supply chain issues, and potential disruptions, allowing teams to address issues before they escalate.

Preventing Critical Downtime, Saving Costs, and Increasing Efficiency

With the right solution in place for real-time connectivity, automotive manufacturers can identify and address supply chain disruptions before they result in critical downtime. Proactively addressing issues eliminates the need for last-minute, expensive solutions like air charters or expedited shipping, reducing overall costs.

End-to-end visibility and communication enable manufacturers to optimize production processes, improving overall efficiency and meeting production targets consistently.

End-to-end visibility and communication enable manufacturers to optimize production processes, improving overall efficiency and meeting production targets consistently.

As automotive companies strive for excellence, embracing the power of HiveMQ and MQTT is the key to driving efficiency and success on the shop floor. Contact us to learn more about how we can help you solve your automotive manufacturing and supply chain challenges or read our white paper: Optimizing Global Operations and Supply Chain for Automotive Manufacturing.

Dominic Iannuzzi

Dominic Iannuzzi has worked in material logistics management, plant management, and operations for leading automotive and transportation companies prior to joining HiveMQ as Enterprise Account Executive for the Automotive Industry. He has experience in sales, management, customer service, marketing and supply chain in various organizations.